Algorithms¶

Specification of .analytic's analysis algorithms, their benefits, and application.

Overview¶

Analytics pursues one goal: Guiding stakeholders in buildings (asset-, property-, facility management) to improve the operational performance of buildings and energy systems. The benefits are multilateral:

- Fast success decarbonizing the building and energy system.

- Higher energy efficiency providing comfort and energy services.

- Higher indoor comfort, means higher well-being and therefore performance of people in buildings.

- More reliable technical building equipment, less wear, and more efficient maintenance.

This page offers specifications on the available analysis functions. Each specification starts with an introduction to the analysis, followed by tabs providing deeper insights and application notes. Browse the tabs for insights in the analysis specifications.

This tab summarizes the value offered by the analysis function, the component types the analysis is recommended for, and the conditions checked by the analysis.

Expect a short case-study on how the analysis function was applied during development or a test bench.

Results of analytics functions are structured to deliver simple-to-navigate insights and fast-to-apply measures on how to improve operational performance.

Therefore, each result regardless of the analytics function includes

- One qualitative warning level, aka. signal color,

- One interpretation,

- Zero to one summary KPI,

- Zero to n recommendations,

- Zero to n KPIs,

- Zero to n plots, and

- Zero to n timeseries.

These categories are explained below. While the warning level, interpretation, and recommendation are specified for all analysis functions equally, summary KPIs, KPIs, plots, and time series differ between each analysis function.

Warning level

The warning level represents the urgency of looking into the analyzed condition and taking action to improve it. It can have one of these traffic light states, but not every analysis makes use of the full spectrum:

Red: Suboptimal performance identified. It can be expected that either improving the identified condition will have a strong effect on the performance or the effort to realize the optimization is moderate compared to its benefit.

Yellow: Suboptimal performance identified. The effort to optimize might consume its benefit. To reduce the effort, implement the measure with the maintenance work that is required anyway. Observation of the analyzed condition is recommended.

Green: Performance is satisfactory. No action is recommended.

Interpretation

The interpretation delivers a summary of the observed performance and state of the condition analyzed. It describes either a symptom of a suboptimal operation or a condition that could be identified.

Recommendation

Recommendations are summarized in a list of zero (for sufficient operational performance) to n measurements on how to improve the operational performance. The recommendations either help by providing information on how to correct the source of the symptom itself or on how to narrow down to its root cause.

Plots

It is easy to understand complex data insights with the right visualization. Thus, many .analytics algorithms offer plotting recommendations including the type of plot, data, and labeling. This structured and well defined plotting data makes it easy to transport data insights.

Available plot types

| Name | Type identifier |

|---|---|

| Bar chart | bar_chart |

| Pie chart | pie_chart |

| Gauge chart | gauge_chart |

| Bullet graph | bullet_graph |

Included data structures

| Key | Info |

|---|---|

| data | Contains the dataset including its "name" and a list of "values" |

| categories | If data contains multiple values, categories can be passed for each. In this case, categories and values are associated by their identical list index. E.g. "values":[50.13, 49.87, 49.01] "categories":["March", "April", "May"] |

| extras | Can contain plottable information, such as thresholds. The thresholds for most plots are static, but Wellbeing thresholds are based on what data is available |

| identifier | Frontend placement context |

| title | Title that is placed above the plot |

| type | Which of the plot types listed above is to be displayed |

| unit | The unit of the plot dataset |

Summary KPIs, KPIs, and time series

KPIs and time series offer insights and transparency, while the most important KPI is offered as summary KPI including its current value and KPI development compared to the previous analysis. They enable reporting and manual investigation of the operational behavior of the component or system analyzed. KPIs and time series are highly individual for each function and are explained in the respective specification of each analysis function in Results.

The Components tab contains the information on how to configure the algorithm for the specific components.

- The components the analysis function is available for,

- The pins of the components which need to be mapped, and

- The attributes of the component required.

The Application tab provides information on the application of the analysis function.

- Recommended time span: Most of the analysis functions have a sweet spot for the amount of historical data required to derive accurate results.

- Recommended repetition: Components of building energy systems are subject to seasonal effects and wear out. Follow the recommended repetition to ensure the analysis is performed as often as necessary, without risking blind spots during the continuous monitoring of the system.

The Further information tab provides supplementary information about possible analysis results. Based on the respective and concise interpretation message, a technical explanation is given.

"Interpretation message"

Explanation

A detailed description of the analysis result.

Suggestion

A detailed description of the given recommendations.

Analysis functions¶

See below for the individual analysis function specification.

Alarm State¶

The Alarm State analysis assesses the occurrences and duration of alarm messages of a component. It is particularly useful for notifying the user when alarm messages have been overseen, as it summarizes the alarm messages over a given time period. Additionally, the Alarm State analysis considers the most recent alarm message to determine whether the error has been resolved. While this analysis can be used for all alarm messages, it is most suited to critical alarm messages.

Value

- Avoids alarm messages being overlooked

- Identifies faulty components

- Can reduce component wear-and-tear

- Can increase energy efficiency

Recommended for components

Any component or subsystem which could have an alarm or error message such as:

- Fans

- Heat pumps

- Thermal control loops

Checked conditions

- Last state of alarm message

- Relative duration of alarm message

- Total duration of alarm messages

- Total occurrences of alarm message

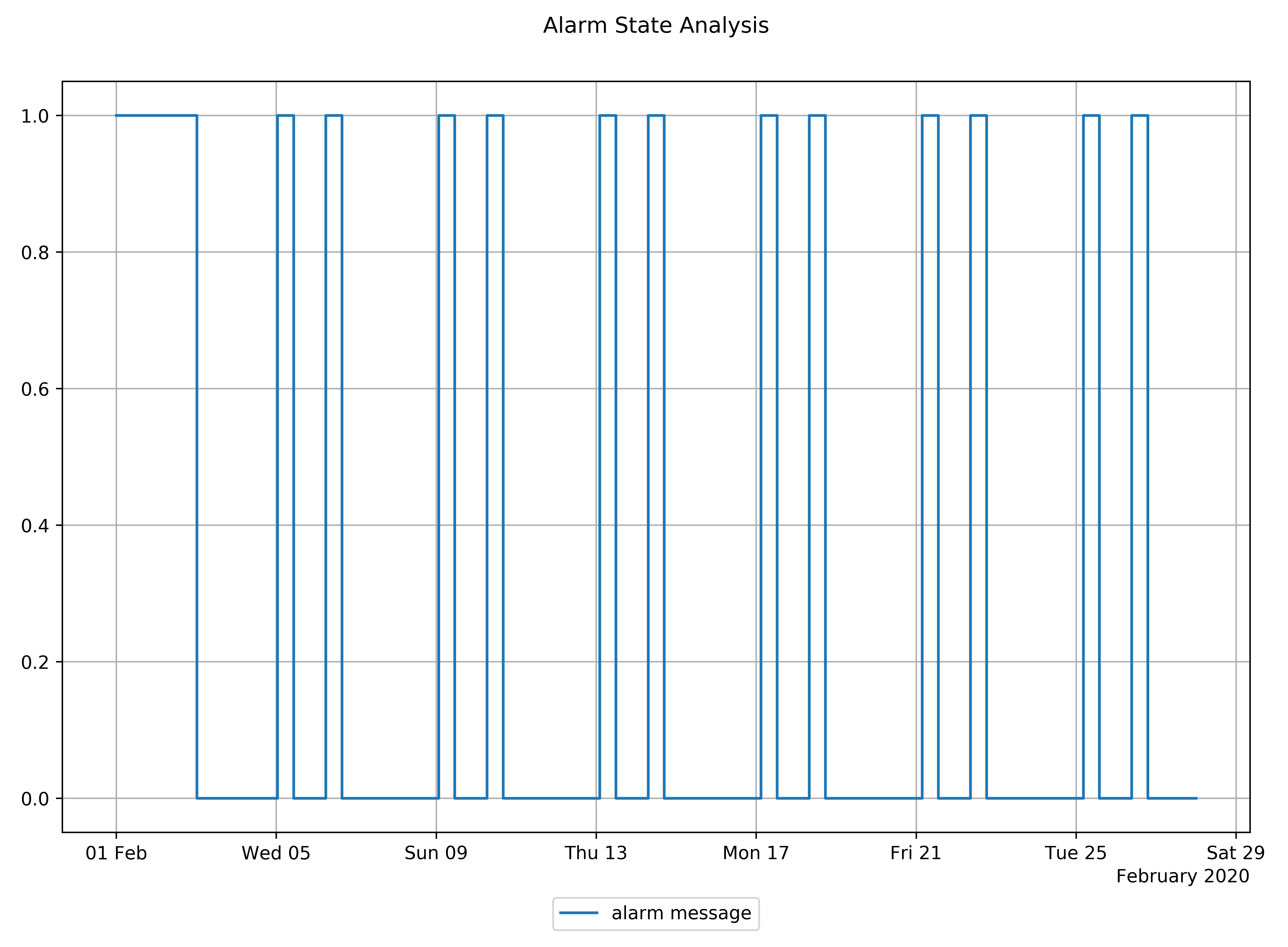

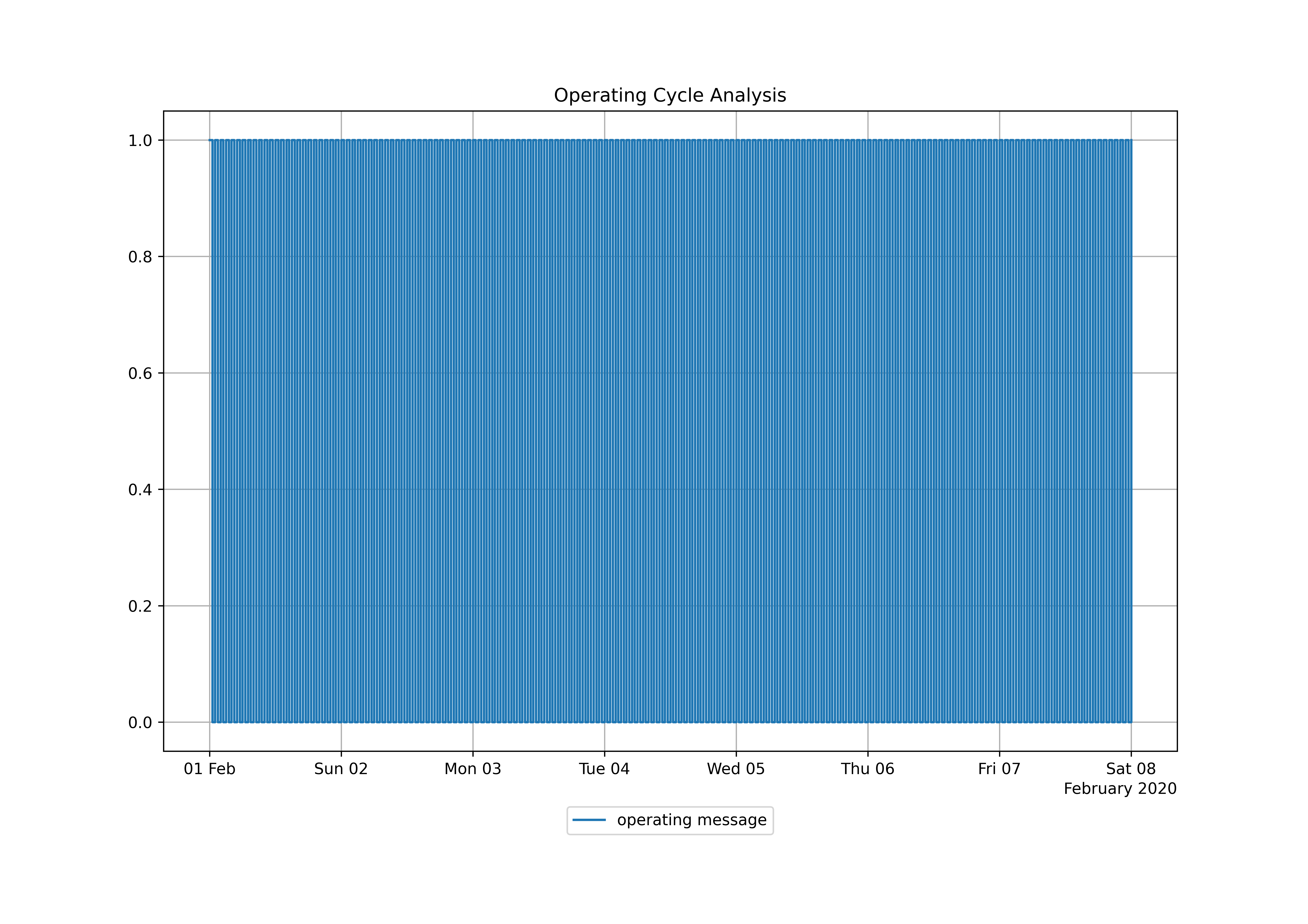

The Alarm State analysis was performed on a component for February 2020. The error message is active at the beginning of the time period and then about twice a week after that.

Figure 1: Component error message for the month of February 2020

The analysis returns a red warning message to indicate that the error message over the time period is suboptimal. This is because the error message is active for a significant percentage of the total time.

| KPI | Value | Unit |

|---|---|---|

| alarm message.last observation | inactive | binary |

| alarm message.relative | 25.4 | % |

| alarm message.duration | 164 | h |

| alarm message.count | 12 | count |

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | Yes | The occurrences or alarm message duration is high and the alarm is active at the end of the analysis. |

| yellow | Yes | The occurrences or alarm message duration is high. |

| green | Yes | The occurrences and alarm message duration are insignificant. |

Interpretations

| Available | Info |

|---|---|

| Yes | Interpretations summarize the result of the analysis. |

Recommendations

| Available | Info |

|---|---|

| Yes | Check the component for physical damage and consider changing the component setting. |

KPIs

Summary of alarm messages

| KPI Identifier | Info | Value Range | Unit |

|---|---|---|---|

| alarm message.last observation | Last available alarm message. | Active, Inactive | binary |

| alarm message.relative | Time of active alarm message as a percentage of total time. | 0 to 100 | % |

| alarm message.duration | Total time of active alarm message. | 0 to inf | h |

| alarm message.count | Occurrences of the alarm message. | 0 to inf | count |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Alarm message | Yes | - |

Recommended Time Span

1 month

Recommended Repetition

Every month

- After changes of operational modes, e.g., transfers to heating mode

- After changes in the control system

- After maintenance of replacements

CO2 Emissions¶

The CO2 Emissions analysis aggregates CO2 emissions caused by the consumed energy indicated by the meter components of the building during the analysis period. The CO2 emissions are related to the net floor area of the building and are benchmarked against the usual emissions for the same type of building.

Value

- ESG-Reporting and monitoring of CO2 emissions

- Insights in CO2 performance of the building

- CO2 emission benchmarking

- Trace back CO2 emissions to energy sources

Recommended for components

Complete buildings or energy systems

Checked conditions

- CO2 emissions of the building or system

- Benchmarking

- Emission by energy source

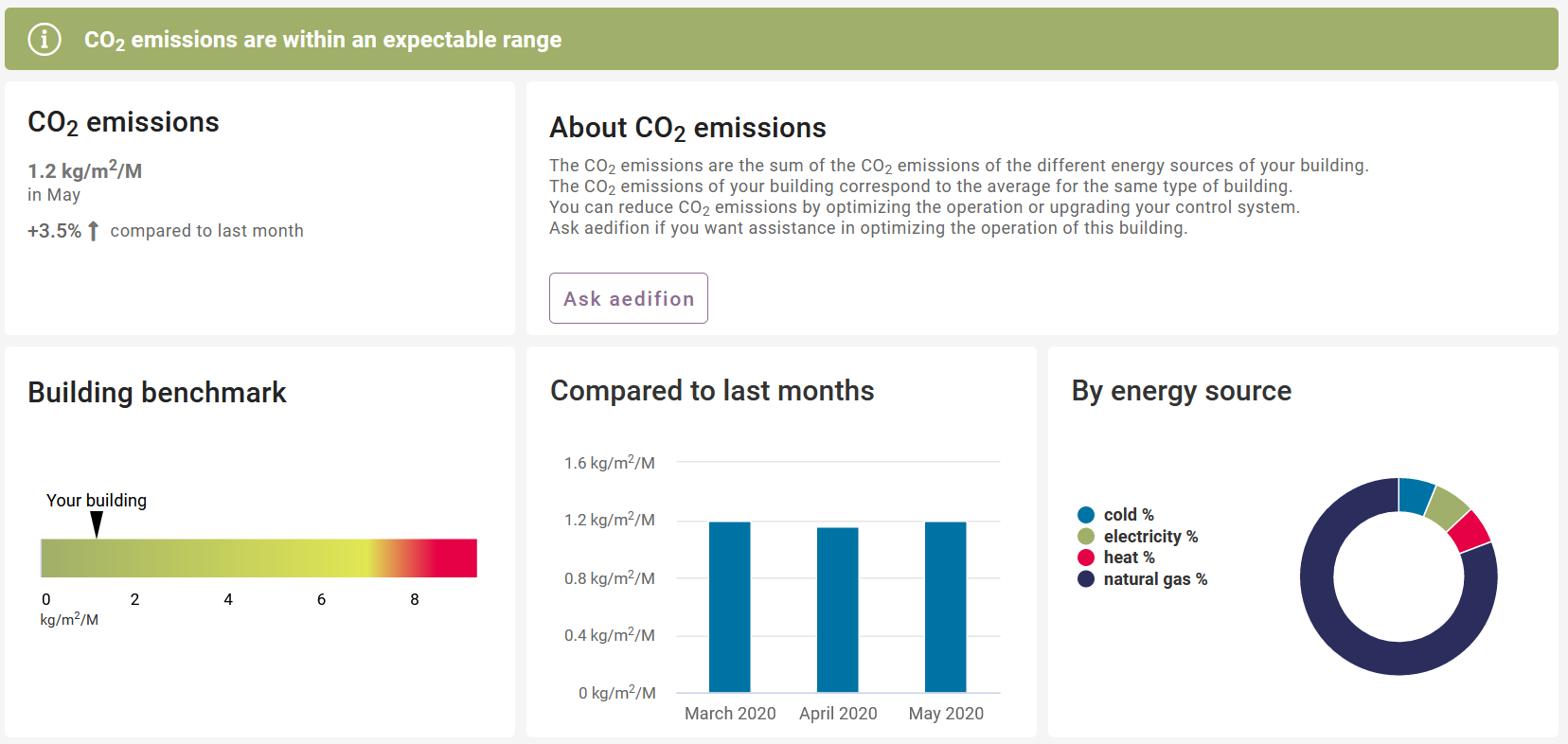

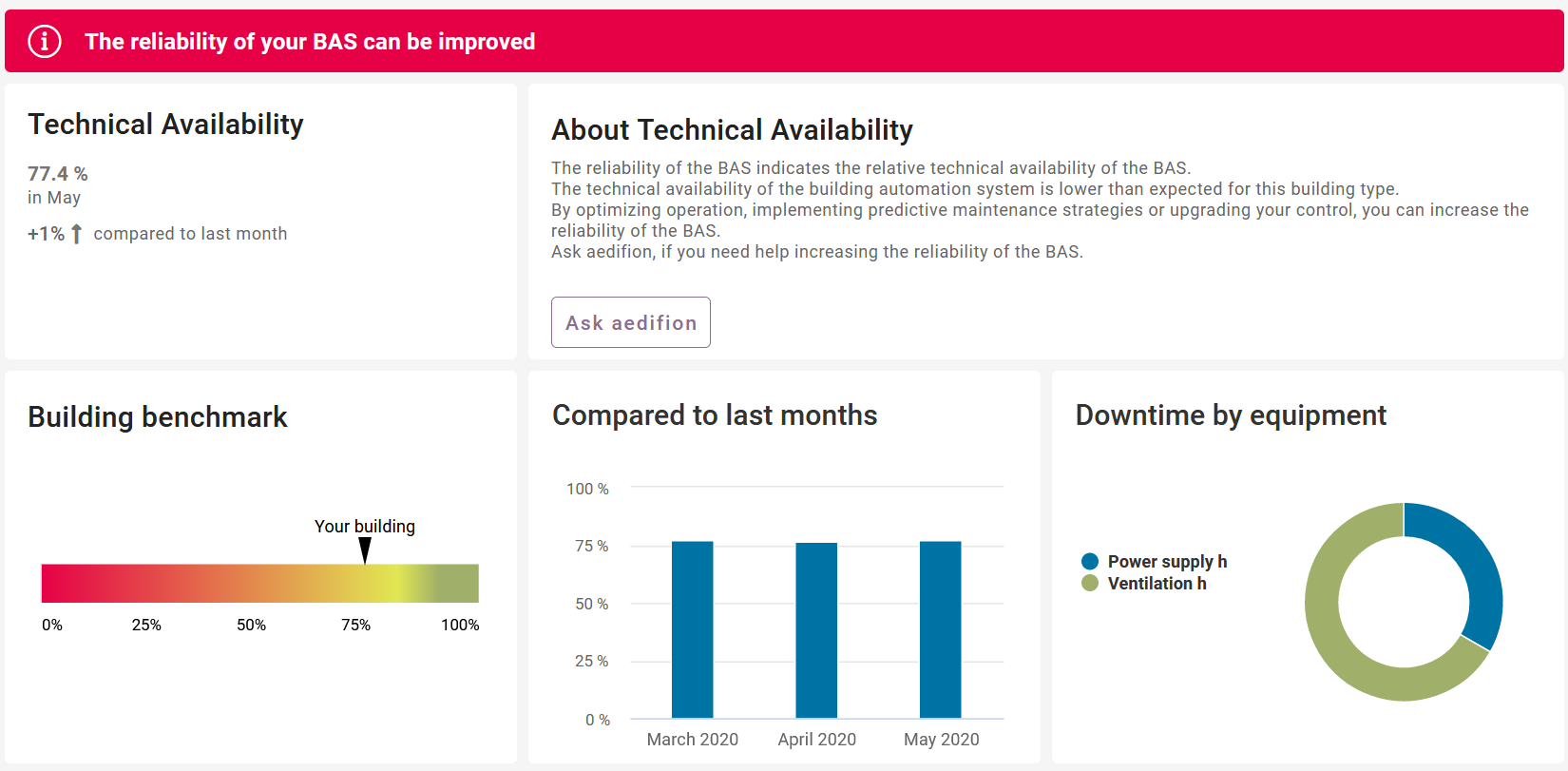

This example shows the results of an CO2 Emission analysis displayed in the Asset Overview.

Figure 1: CO2 emissions Asset Overview result overview

Above all cards the interpretation text of the result is highlighted with the signal color of the result. In the top left the current KPI and the monthly trend is shown. On the right side of that you will find the recommendations of this result as well as further information about the function.

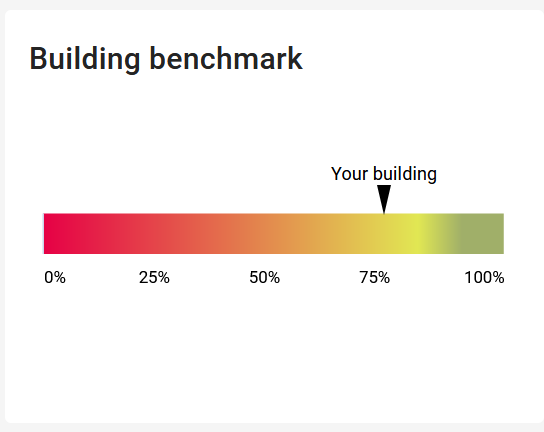

The three plots below are:

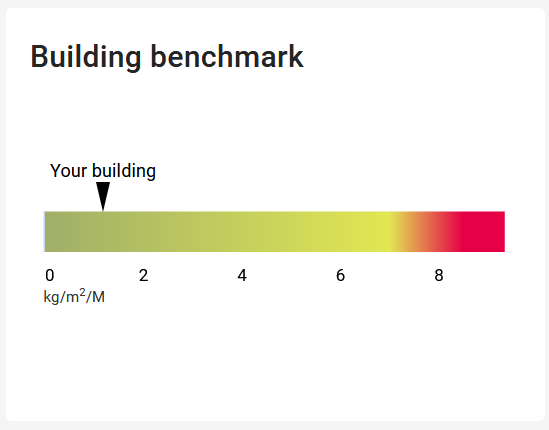

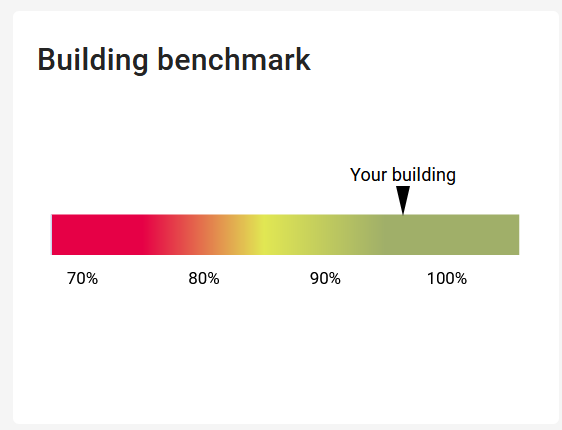

- The building benchmark

Figure 2: CO2 emissions Asset Overview plot bullet graph

The current KPI is plotted inside a bullet graph between the limits of the signal color.

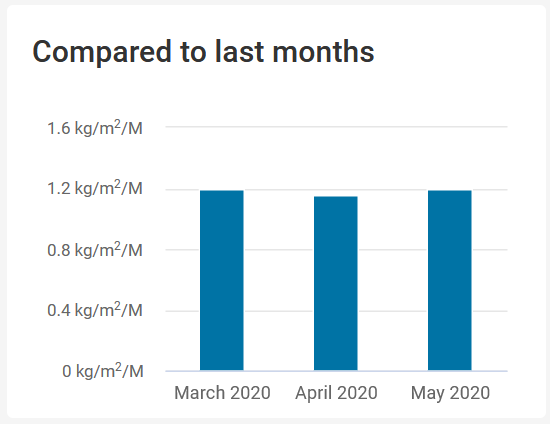

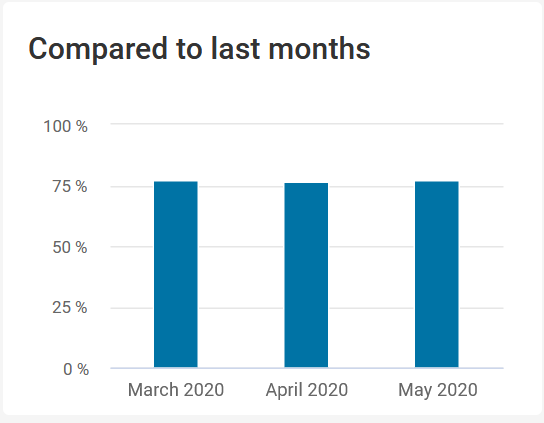

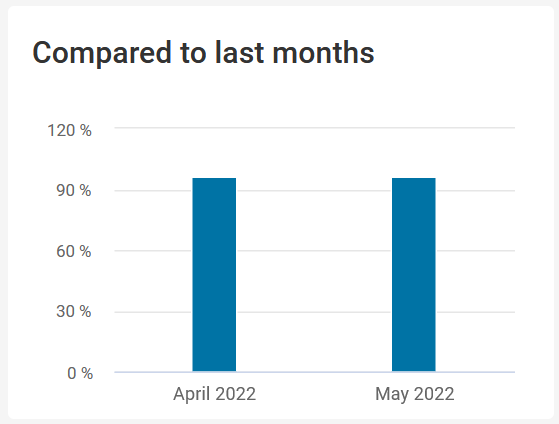

- Compared to last months

Figure 3: CO2 emissions Asset Overview plot month comparison

The plot shows the current KPI of the last three months, including the month of the analysis.

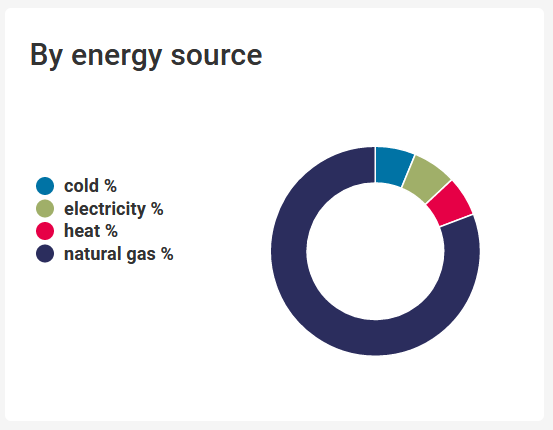

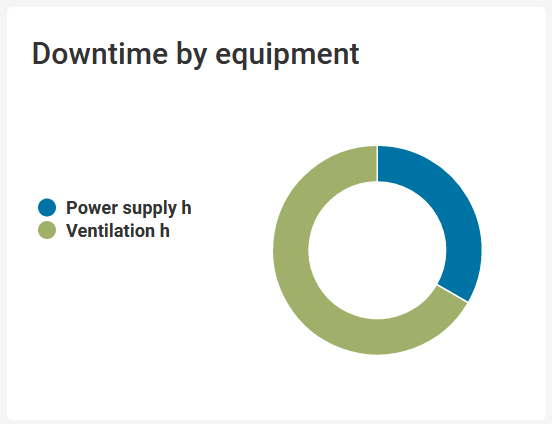

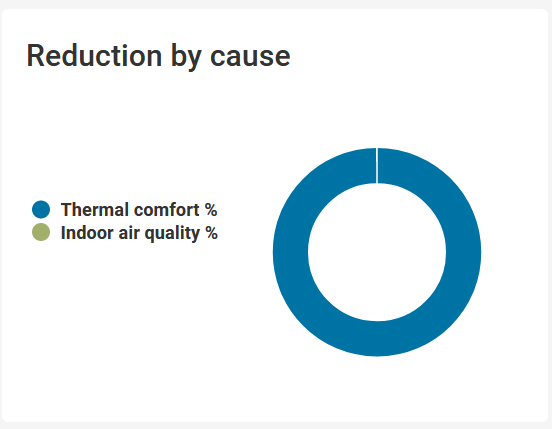

- By energy source

Figure 4: CO2 emissions Asset Overview plot energy source

The plot shows the distribution of CO2 emissions by energy source.

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | Yes | CO2 emission significantly above average for this type of building. |

| yellow | Yes | CO2 emission significantly above average for this type of building. |

| green | Yes | CO2 emission below average for this type of building. |

Interpretations

| Available | Info |

|---|---|

| Yes | Interpretations summarize the result of the analysis. |

Recommendations

| Available | Info |

|---|---|

| Yes | Info text and recommendation for action. |

KPIs

Summary KPI

| KPI reference | Info | Value Range | Unit |

|---|---|---|---|

| current | Aggregated CO2 emission during analysis period of one month, specific to the net flor area of the building | -inf to inf | kg/m2/M |

| development | Change in CO2 emission compared to last analysis period | -inf to inf | % |

Timeseries

The timeseries is saved as a virtual datapoint. Every run of the analysis will add the summary KPI (current value) as an observation at the start of the analysis period to the timeseries.

| Timeseries datapointID | Info | Unit |

|---|---|---|

| {project_id}_{instance_id}_co2_emissions_absolute | Absolute CO2 emissions timeseries | kg |

| {project_id}_{instance_id}_co2_emissions | Specific CO2 emissions timeseries | kg/m2/M |

Plots

| Identifier | Type | Info | Unit |

|---|---|---|---|

| benchmark | bullet_graph | CO2 benchmarking including color scale Default: Based on German Gebäudeenergiegesetz | kg/m2/M |

| month_comparison | bar_chart | CO2 emissions of the last 3 months | kg/m2/M |

| co2_emissions | pie_chart | CO2 emission by energy source | % |

| Pin | Required | Mapping info | Unit |

|---|---|---|---|

| - | - | - | - |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| CO2 emissions limit red | No | Overwrite the red limit for the CO2 emissions KPI for this building | kg/m2/M |

| CO2 emissions limit yellow | No | Overwrite the yellow limit for the CO2 emissions KPI for this building | kg/m2/M |

| Net floor area | Yes | Used to calculate the per area KPI for current value | m2 |

Sub-components

At least one sub-component is needed to get a result for this analysis function. Only the necessary meter components need to be added to the project.

| Pin | Required | Mapping info |

|---|---|---|

| CO2 emission factor | No | CO2 emission factor for the underlying energy in kg CO2/kWh. Alternative for the corresponding attribute. If the attribute is set the pin is not considered inside the analysis. |

| Cooling energy | Yes | Cumulating timeseries in kWh |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| CO2 emission factor | No | CO2 emission factor for the underlying energy. If the attribute is set the corresponding pin is not considered inside the analysis. | kg CO2/kWh |

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

| Pin | Required | Mapping info |

|---|---|---|

| Active energy | Yes | Cumulating timeseries in kWh |

| CO2 emission factor | No | CO2 emission factor for the underlying energy in kg CO2/kWh. Alternative for the corresponding attribute. If the attribute is set the pin is not considered inside the analysis. |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| CO2 emission factor | No | CO2 emission factor for the underlying energy. If the attribute is set the corresponding pin is not considered inside the analysis. | kg CO2/kWh |

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

| Pin | Required | Mapping info |

|---|---|---|

| CO2 emission factor | No | CO2 emission factor for the underlying energy in kg CO2/kWh. Alternative for the corresponding attribute. If the attribute is set the pin is not considered inside the analysis. |

| Gas quantity | Yes | Cumulating timeseries in m3, calorific_value = 13.0 kWh/m3 |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| CO2 emission factor | No | CO2 emission factor for the underlying energy | kg CO2/kWh |

| Calorific value of natural gas | No | Change to calorific value of delivered natural gas. Default: 13 kWh/m3 | kWh/m3 |

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

| Pressure compensation factor of natural gas | No | Additional factor to compensate for elevation and line pressure at the termination point. Default: 1 |

| Pin | Required | Mapping info |

|---|---|---|

| CO2 emission factor | No | CO2 emission factor for the underlying energy in kg CO2/kWh. Alternative for the corresponding attribute. If the attribute is set the pin is not considered inside the analysis. |

| Heating energy | Yes | Cumulating timeseries in kWh |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| CO2 emission factor | No | CO2 emission factor for the underlying energy. If the attribute is set the corresponding pin is not considered inside the analysis. | kg CO2/kWh |

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

Recommend Time Span

1 month

Recommended Repetition

Monthly

- Continuously monitor CO2 emissions

- Track success of a decarbonization measure

Control Loop Oscillation¶

The Control Loop Oscillation analysis checks the process value of a control loop for oscillation. Oscillating process values are an indicator for suboptimal parameterization or structural dimensioning of the control loop.

Value

- Increase lifetime of valve, dampers, and adjacent components

- Avoid spontaneous failures

- Reduce energy consumption

- Reduce noise pollution

Recommended for components

Any liquid media supply system, such as:

- Thermal control loop with 2-way valve and pump

Checked conditions

- Process value of the control loop is oscillating

- Process value of the control loop is not or to a negligible degree oscillating

- Condition checks on times of components operation

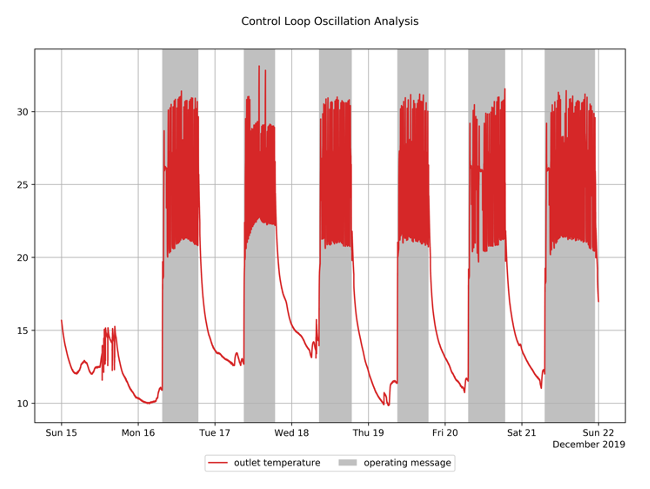

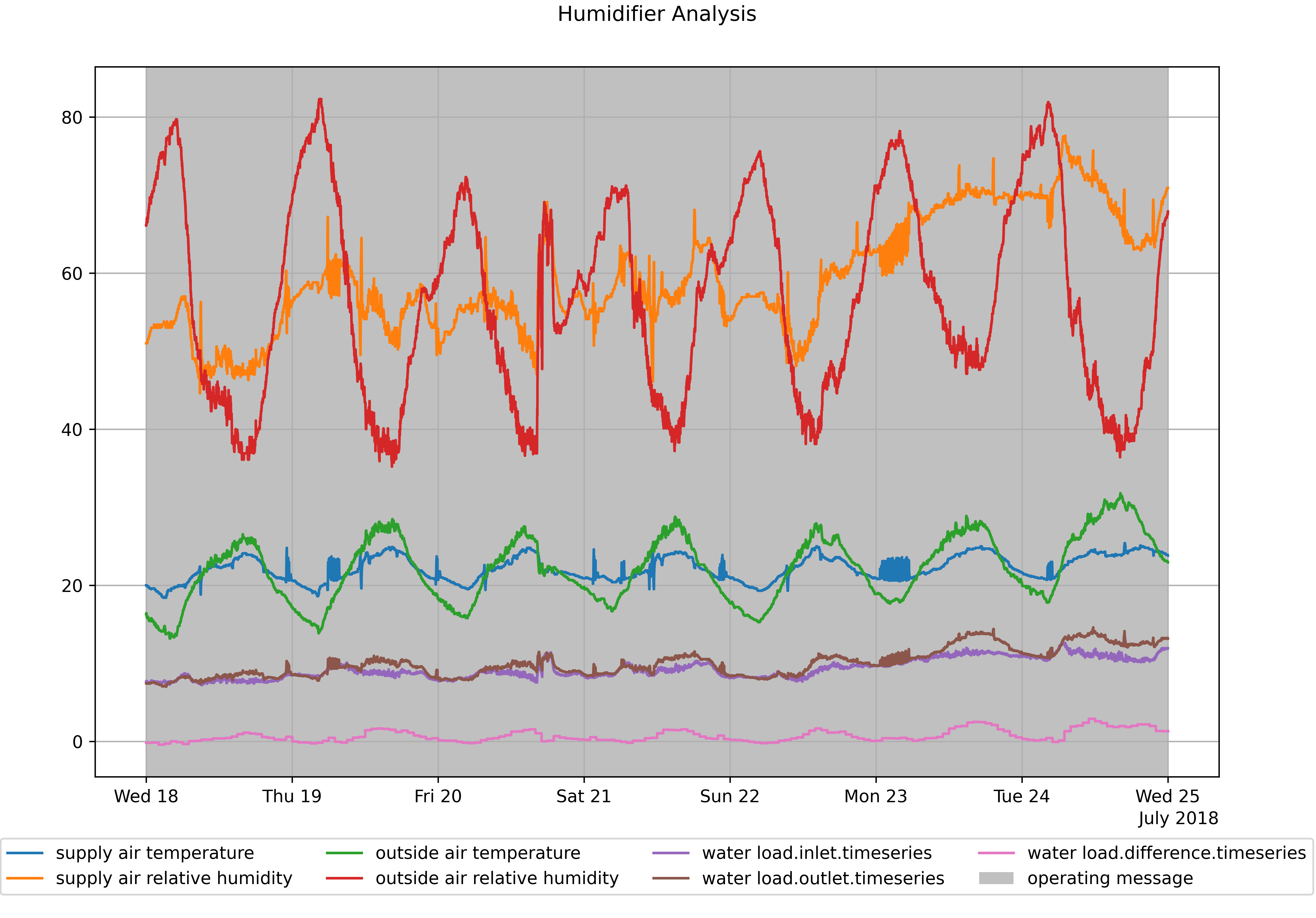

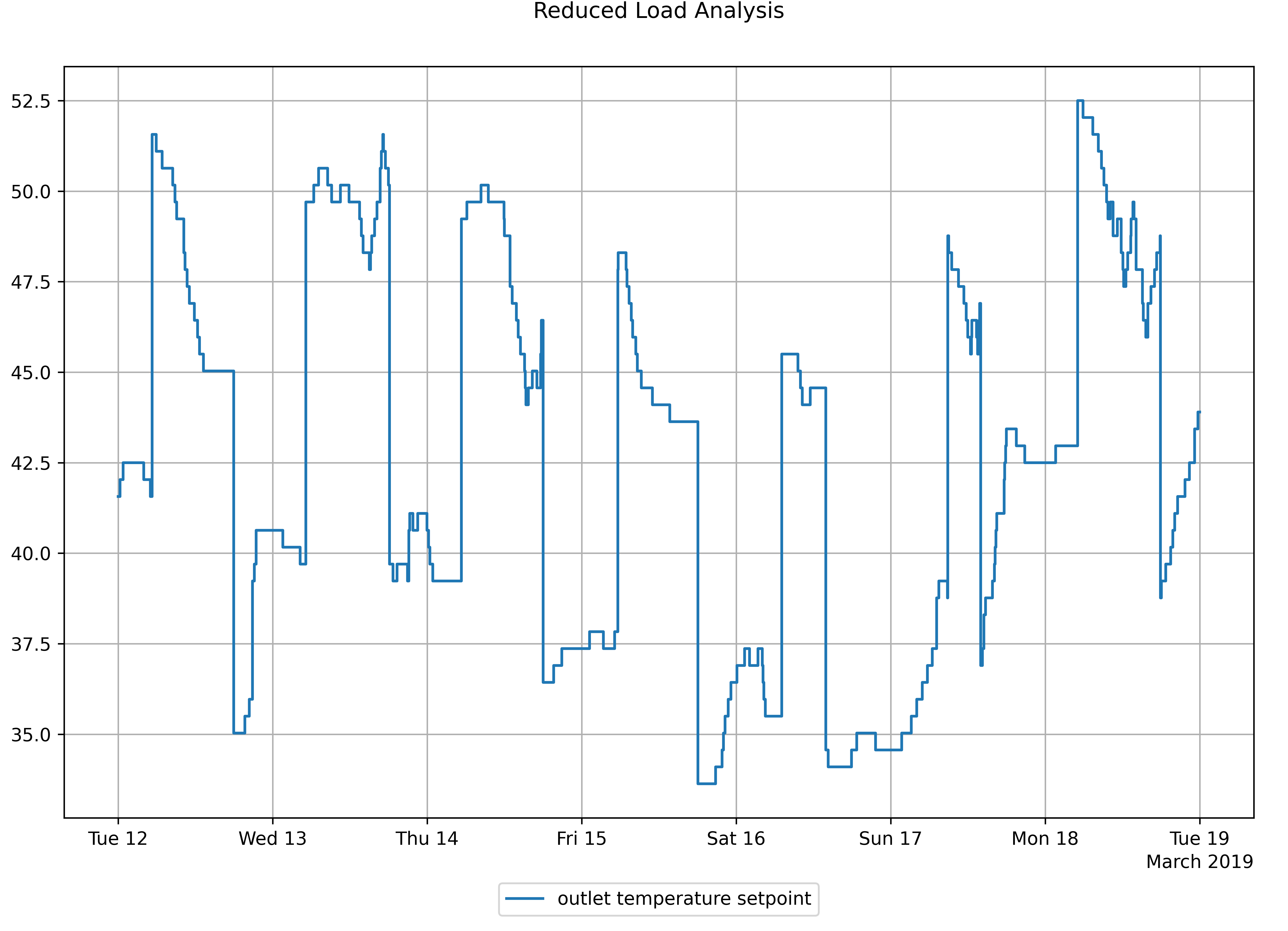

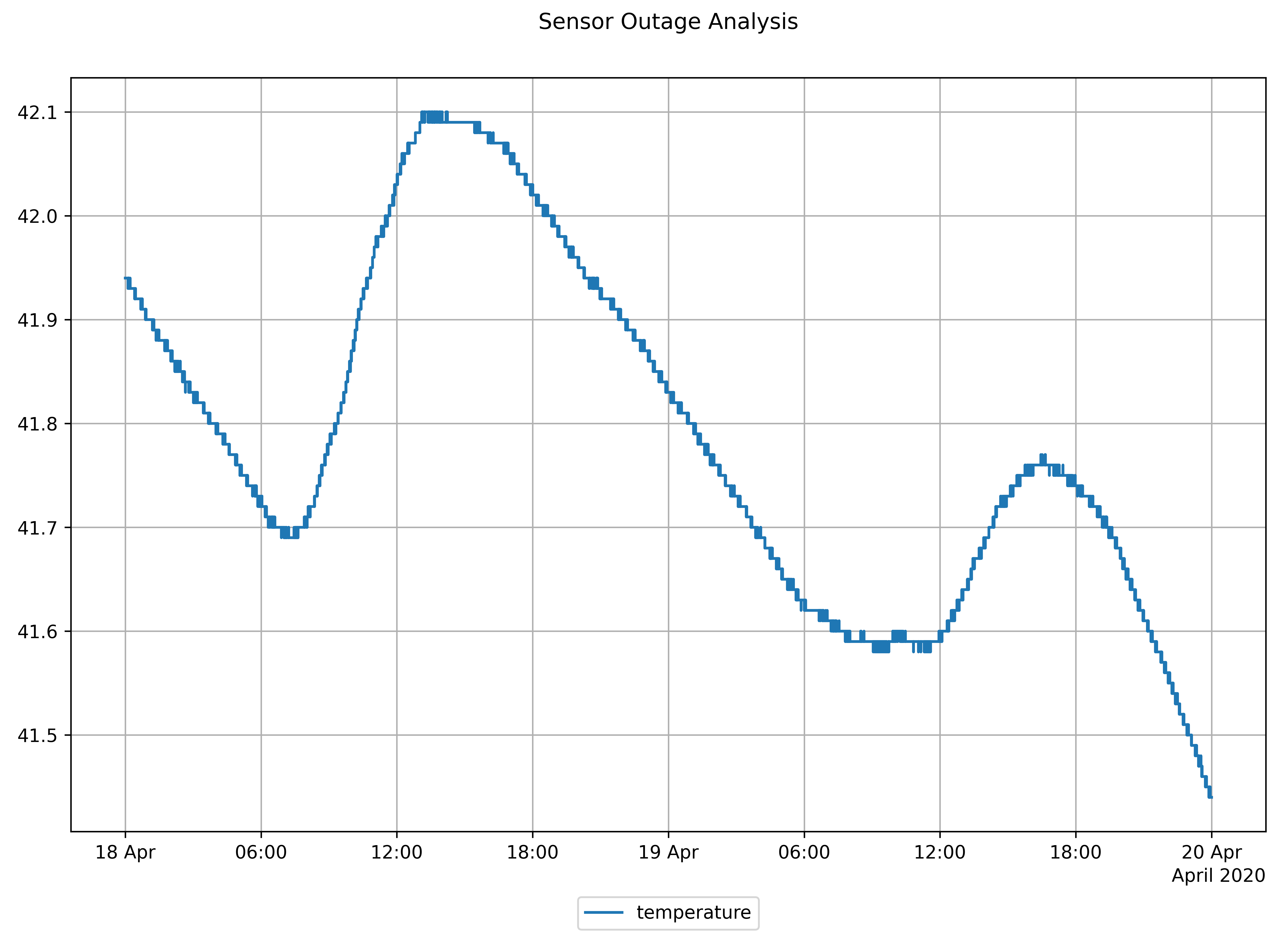

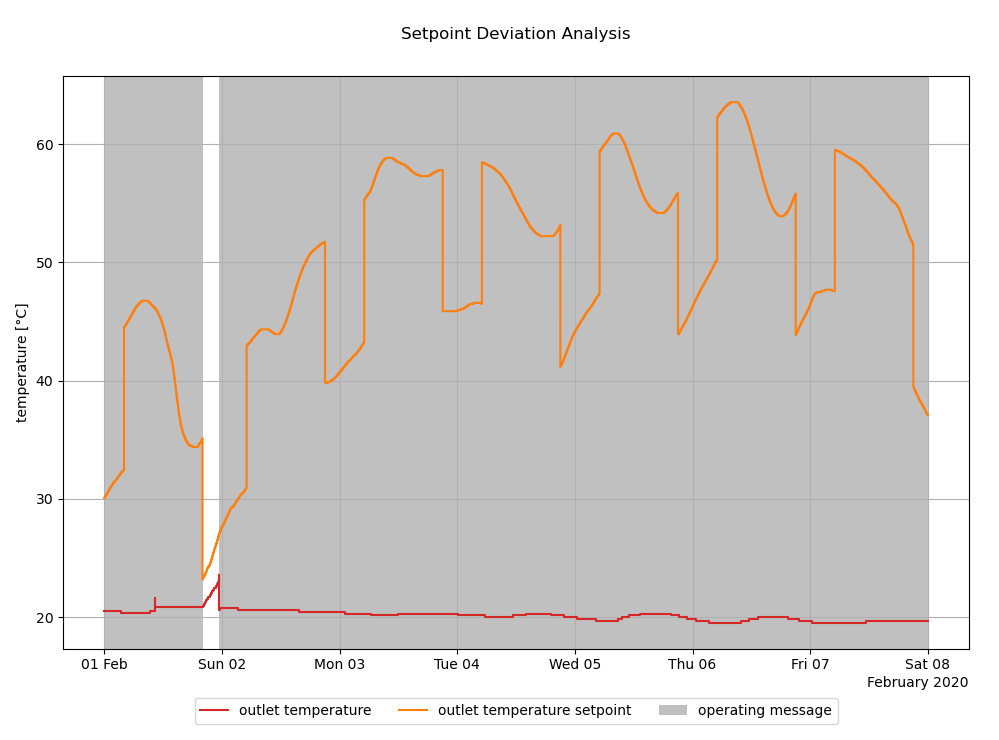

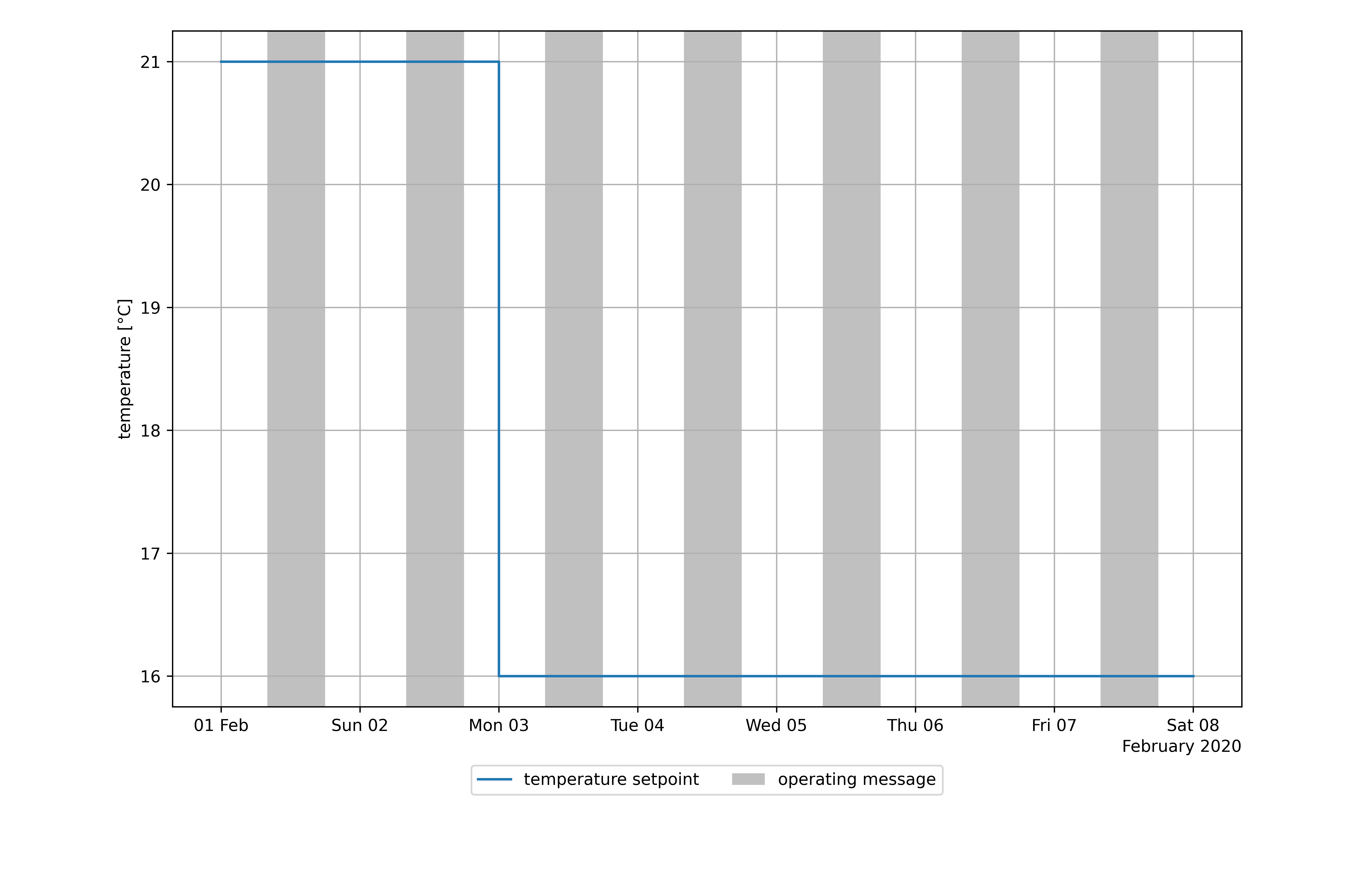

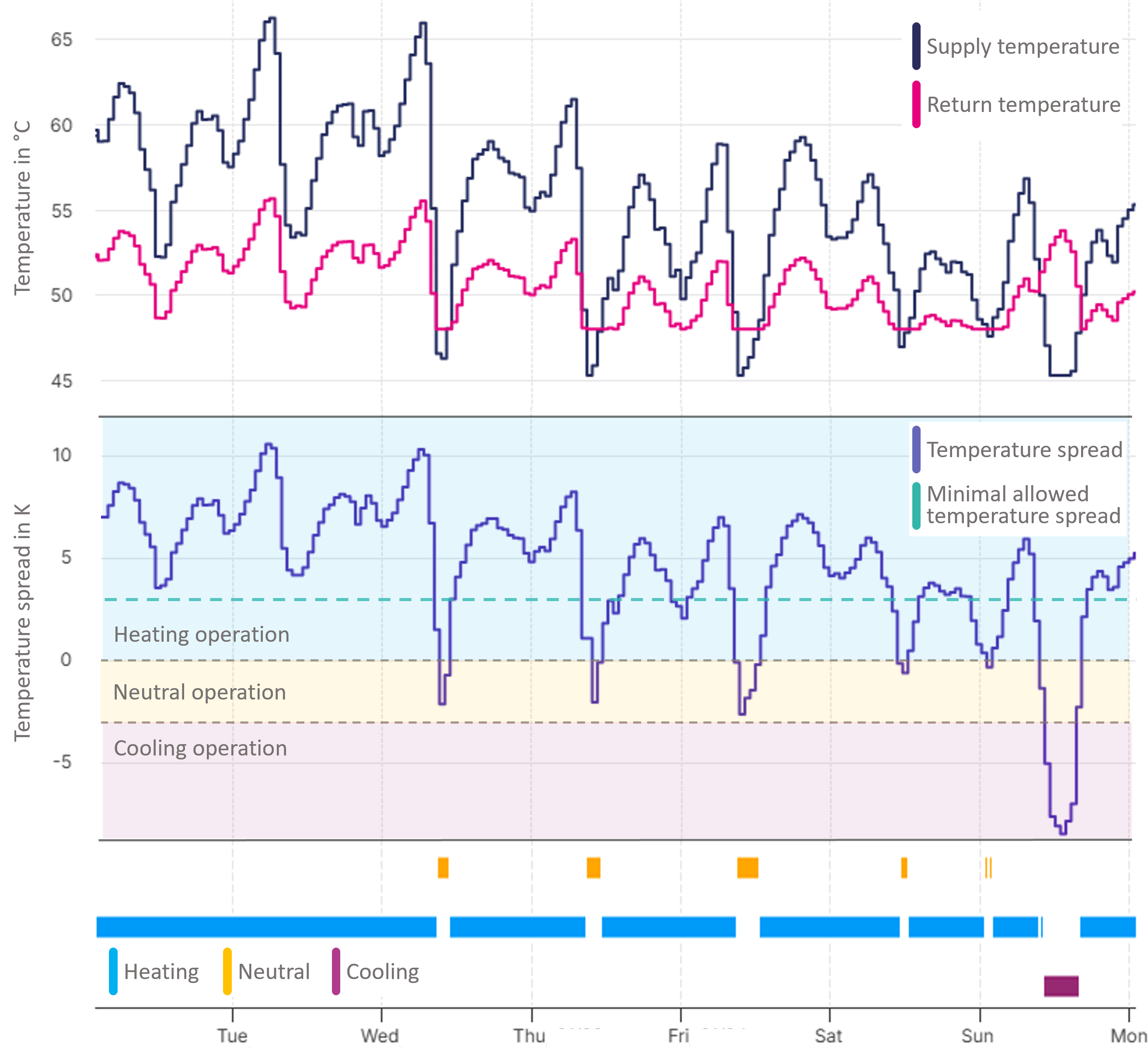

For this example, we analyzed the temperature control loop of a supply air volume flow, which provides fresh air and heating to a large salesroom. Figure 1 shows a plot of the process value of the control loop, the outlet temperature. The plot shows an oscillation of the outlet temperature during periods of operation.

Figure 1: Oscillating processes value during operation

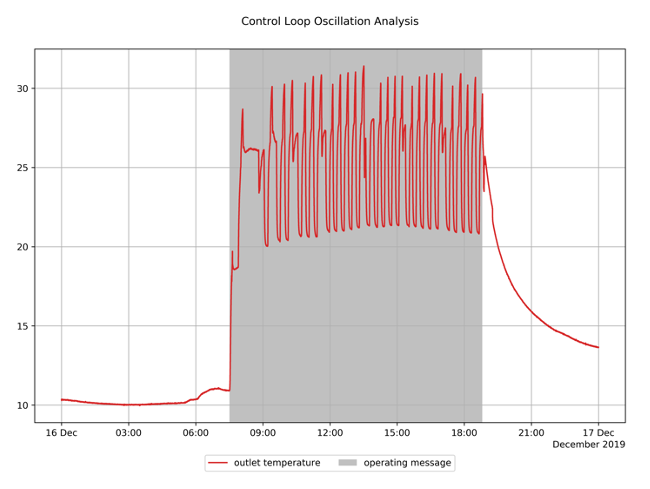

Figure 2 is a zoom of figure 1 to analyze the oscillation in more detail. The trajectory of the process value is common for control loops oscillating at medium frequency.

Figure 2: Oscillating process value during operation in detail

The Control Loop analysis evaluated this oscillation as significant and assigned it the signal color yellow. Recommendations are made on how to adjust controller parameters for a smoother operation.

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | No | Red as a signal for a low cost measure with high impact on the building operation will not be provided. |

| yellow | Yes | An oscillating control loop is a symptom for suboptimal control parameters or component design. Investing the extra effort to identify the root cause and fixing it is strongly recommended. |

| green | Yes | No or only slight, in respect to usual tolerances in buildings, negligible oscillation. |

Interpretations

| Available | Info |

|---|---|

| Yes | Interpretations summarize the result of the analysis. |

Recommendations

| Available | Info |

|---|---|

| Yes | Recommendations on how to smooth the control loop oscillation. No recommendation, if oscillation is negligible. |

| Pin | Required | Mapping info |

|---|---|---|

| Operating message | No | Strongly recommended Default: Always on |

| Supply air temperature | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Operating message | No | Strongly recommended Default: Always on |

| Supply temperature | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Operating message | No | Strongly recommended Default: Always on |

| Supply temperature - secondary | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Operating message | No | Strongly recommended Default: Always on |

| Supply temperature | Yes | - |

| Pin | Required | Mapping info |

|---|---|---|

| Operating message | No | Strongly recommended Default: Always on |

| Outlet temperature | Yes | - |

Recommend Time Span

1 day to 1 week

Recommended Repetition

Weekly

- After changes of operational modes, e.g., transfers to heating mode

- After changes in the control system

- After maintenance or replacements

Control Sequence¶

The Control Sequence analysis determines the operating modes of a system and compares these with predefined reference modes. The reference modes consist of normal (allowed) operating modes such as heating or dehumidification and faulty (not allowed) operating modes such as simultaneous heating and cooling.

Value

- Better understanding of the system's operating modes

- Detecting of faulty operation modes

- Lower the energy costs of your system through the optimization of the detected operating modes

Recommended for components

- Air handling unit

Checked faulty conditions

- Air heating without full use of the heat recovery system

- Simultaneous heating and cooling

- Contradicting operating modes in downstream air heating or cooling units

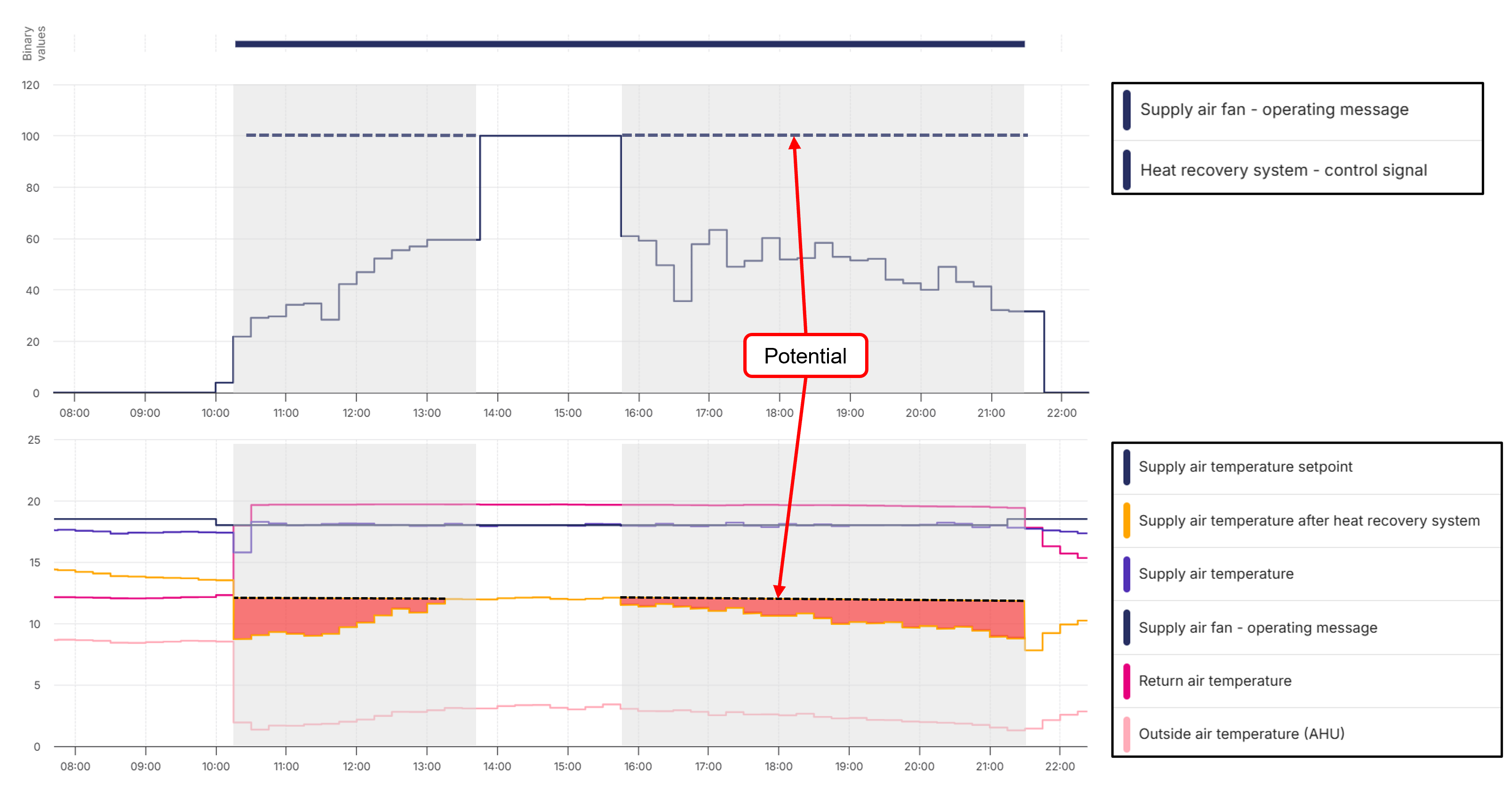

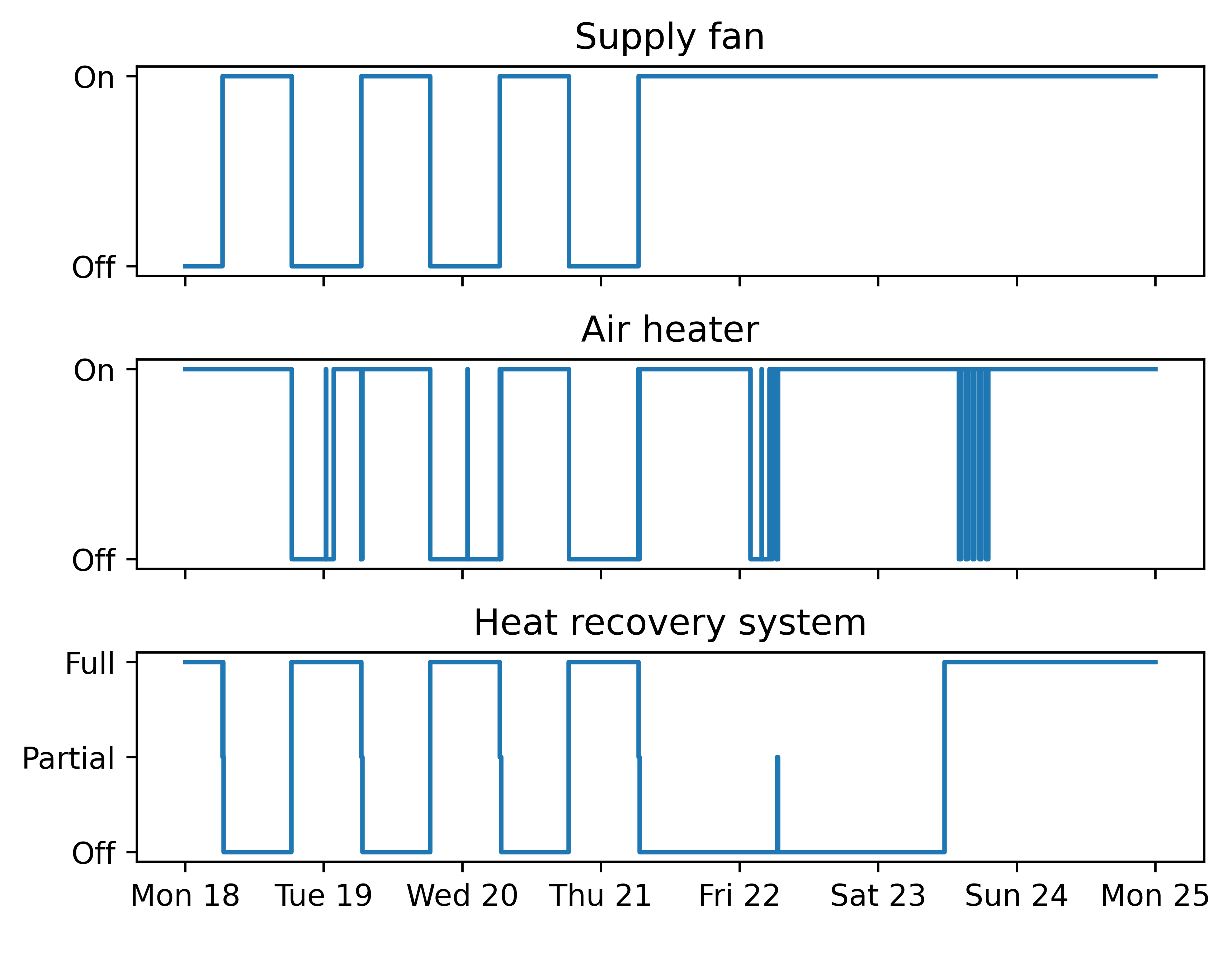

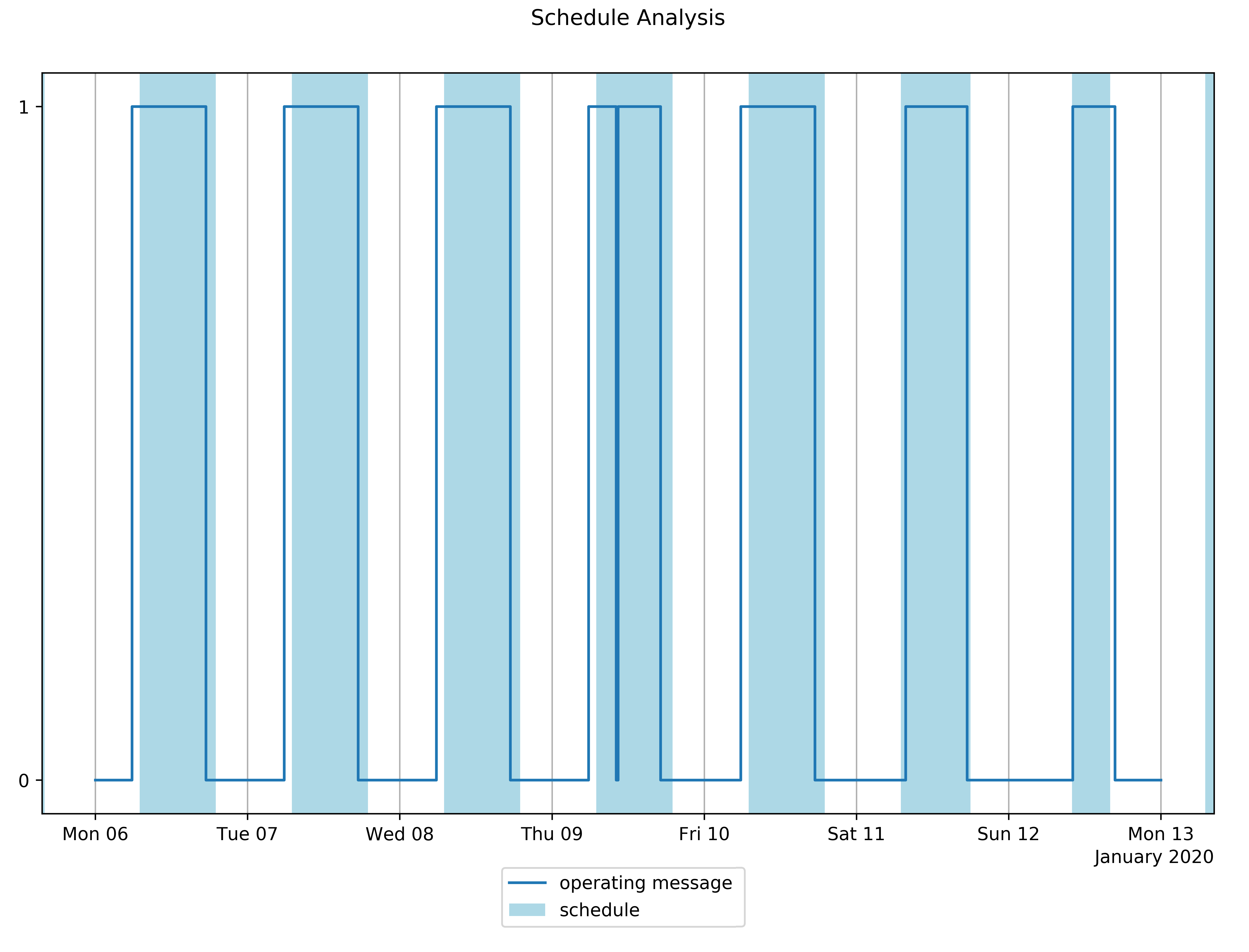

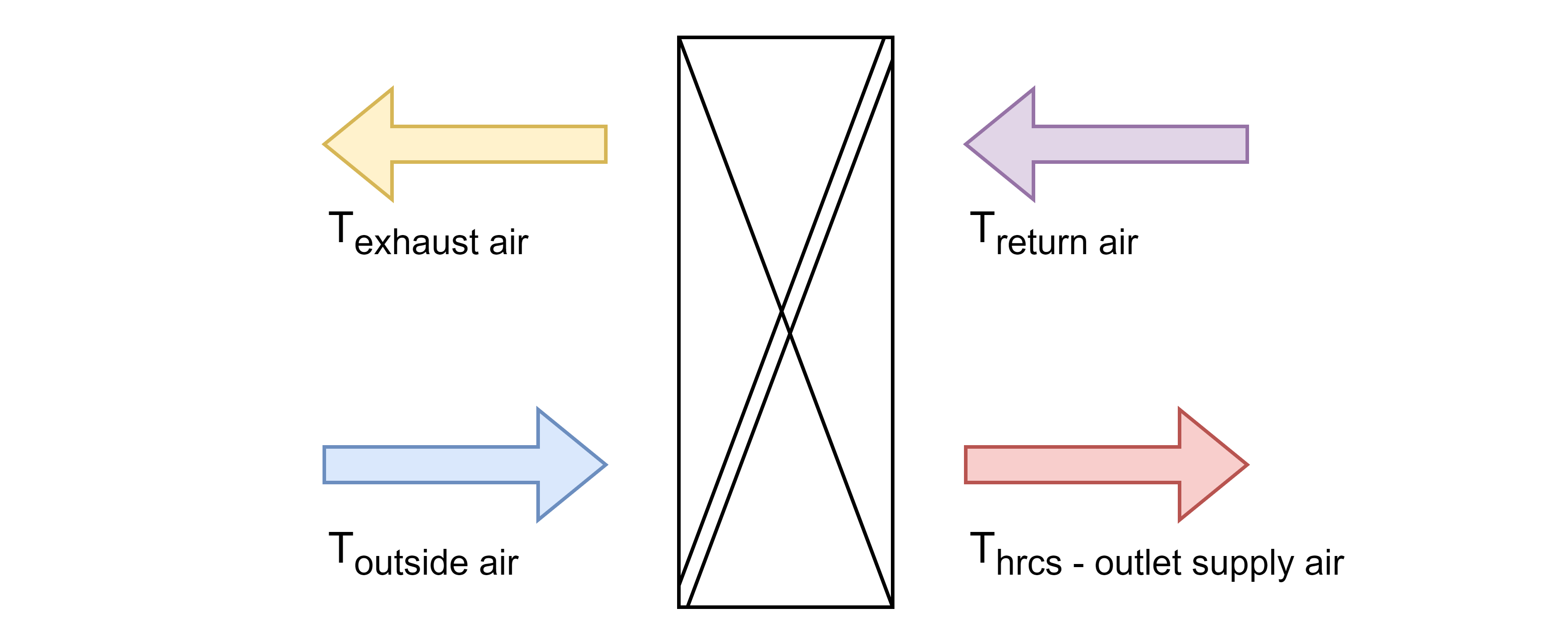

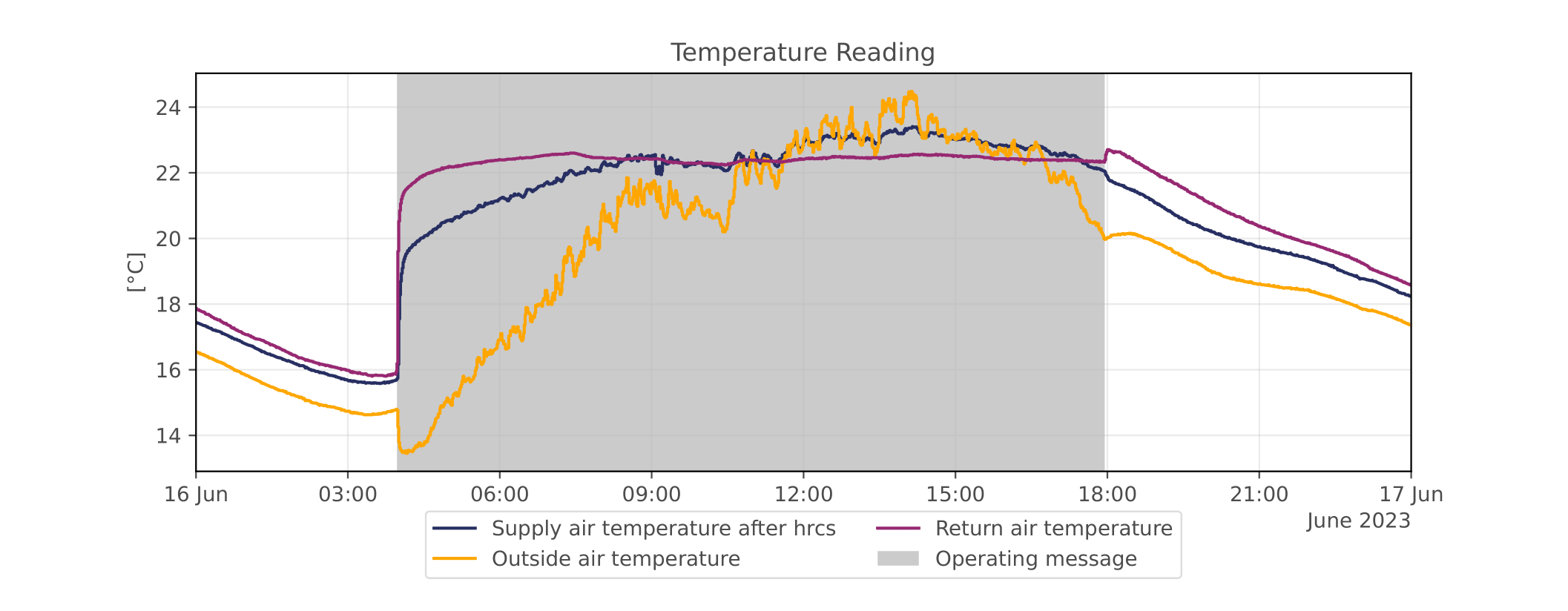

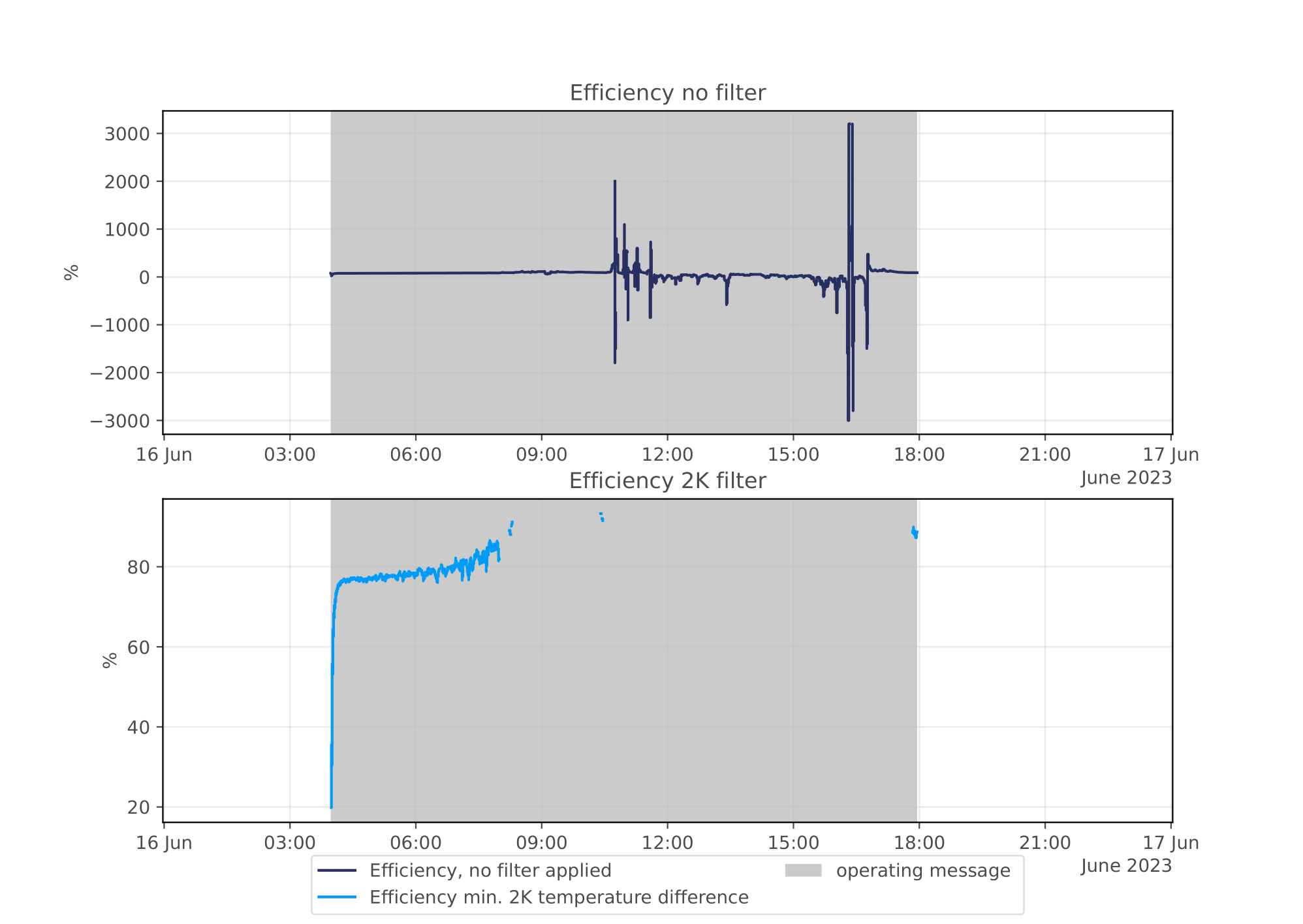

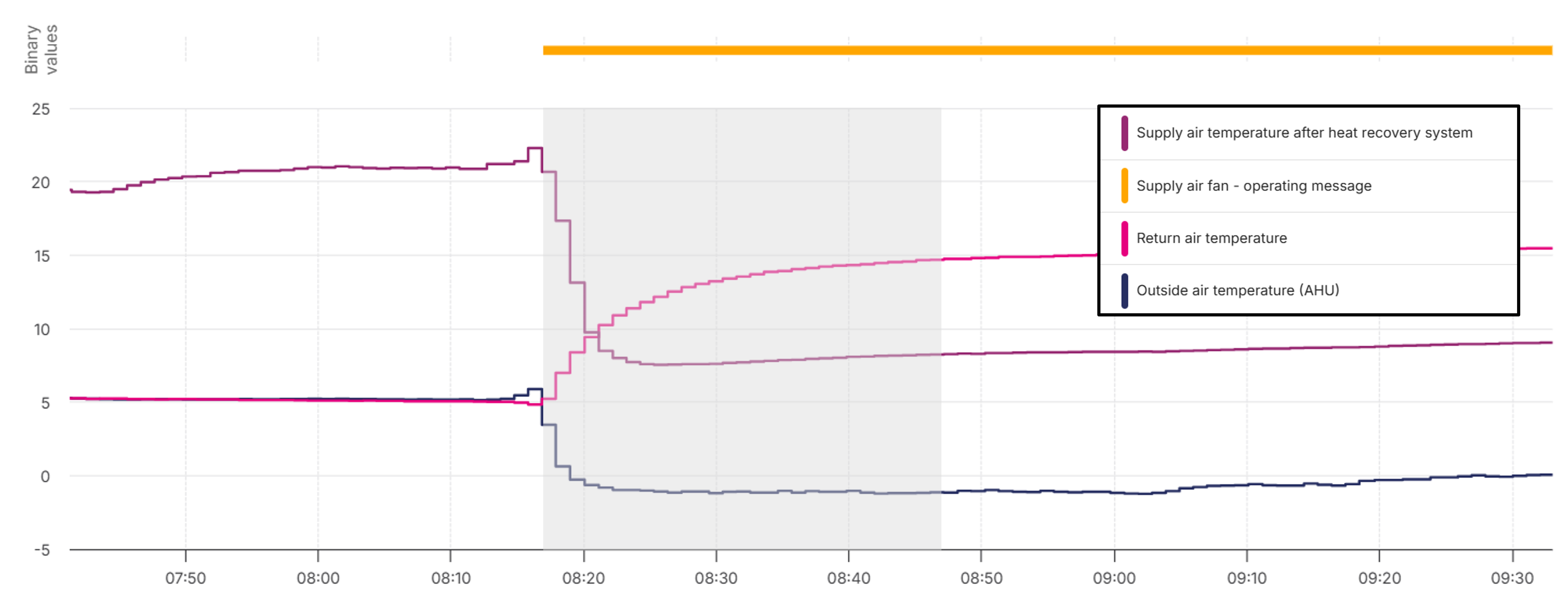

The sequence analysis was applied to an air handling unit with an analysis period of one week. We can see that the unit has been operating in the faulty air heater mode for a very long time. This suggests that the heat recovery is not fully utilized before the air heater is switched on.

Connected sub-components:

- Supply fan

- Air heater

- Heat recovery system

Figure 1: Operating state of sub-components

| KPI | Value | Unit |

|---|---|---|

| operating time | 136.9 | h |

| duration.faulty mode.Air heating without HRCS | 84.4 | h |

| duration.faulty mode.Air heating without HRCS.relative | 50.2 | % |

| duration.mode.Air heating & heat recovery | 34.9 | h |

| duration.mode.Air heating & heat recovery.relative | 20.8 | % |

| duration.mode.Off | 31.1 | h |

| duration.mode.Off.relative | 18.5 | % |

| duration.mode.Antifreeze protection air heater | 11.5 | h |

| duration.mode.Antifreeze protection air heater.relative | 6.83 | % |

| duration.mode.Ventilation | 3.71 | h |

| duration.mode.Ventilation.relative | 2.21 | % |

| duration.mode.Air heating with heat recovery without air heater | 2.44 | h |

| duration.mode.Air heating with heat recovery without air heater.relative | 1.45 | % |

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | Yes | One or more faulty operating modes were found and at least one duration is above the red limit. |

| yellow | Yes | One or more faulty operating modes were found and at least one duration is above the yellow limit. |

| green | Yes | No faulty operating modes detected or no duration of faulty operating modes exceeds the threshold. |

Interpretations

| Available | Info |

|---|---|

| Yes | Interpretations summarize the result of the analysis. |

Recommendations

| Available | Info |

|---|---|

| Yes | Recommendations to avoid operation in a faulty operating mode. |

KPIs

<OPERATING_STATE> refers to the actual detected operating state.

Faulty operating states

| KPI Identifier | Info | Value Range | Unit |

|---|---|---|---|

| duration.faulty mode.<OPERATING_STATE> | Amount of time the corresponding faulty operating state was active during the analysis period. | 0 to inf | h |

| duration.faulty mode.<OPERATING_STATE>.relative | Amount of time the corresponding faulty operating state was active during the analysis period, relative to the analysis period. | 0 to 100 | % |

Normal operating states

| KPI Identifier | Info | Value Range | Unit |

|---|---|---|---|

| duration.mode.<OPERATING_STATE> | Amount of time the corresponding normal operating state was active during the analysis period. | 0 to inf | h |

| duration.mode.<OPERATING_STATE>.relative | Amount of time the corresponding normal operating state was active during the analysis period, relative to the analysis period. | 0 to 100 | % |

| Pin | Required | Mapping info |

|---|---|---|

| Operating message | No | Operating message of the entire AHU system. This pin, if connected, determines whether the function is executed. |

The operating state of the sub-components is determined according to the connected pins of the corresponding sub-component. If no pins are mapped to a sub-component, it is assumed that the air handling unit does not contain this sub-component.

Decentralized downstream air heating and air cooling units are considered as sub-components if they are related to the AHU.

Different pin candidates are available to determine the operating state of the respective sub-component. If several pin candidates of the same sub-component are mapped, the pin with the highest priority is used. The tables of the pin candidates of the sub-components are sorted in descending order of priority.

Sub-component supply fan

| Pin | Required | Mapping info |

|---|---|---|

| Supply fan - operating message | No | This pin is used to determine the operating state of the supply fan. |

| Supply fan - speed | No | This pin is used to determine the operating state of the supply fan. |

Sub-component exhaust fan

| Pin | Required | Mapping info |

|---|---|---|

| Exhaust fan - operating message | No | This pin is used to determine the operating state of the exhaust fan. |

| Exhaust fan - speed | No | This pin is used to determine the operating state of the exhaust fan. |

Sub-component air cooler

| Pin | Required | Mapping info |

|---|---|---|

| Air cooler - operating message | No | This pin is used to determine the operating state of the air cooler. |

| Air cooler - pump operating message | No | This pin is used to determine the operating state of the air cooler. |

| Air cooler - valve position | No | This pin is used to determine the operating state of the air cooler. |

| Air cooler - valve control signal | No | This pin is used to determine the operating state of the air cooler. |

Sub-component air heater

| Pin | Required | Mapping info |

|---|---|---|

| Air heater - operating message | No | This pin is used to determine the operating state of the air heater. |

| Air heater - pump operating message | No | This pin is used to determine the operating state of the air heater. |

| Air heater - valve position | No | This pin is used to determine the operating state of the air heater. |

| Air heater - valve control signal | No | This pin is used to determine the operating state of the air heater. |

Sub-component air re-heater

| Pin | Required | Mapping info |

|---|---|---|

| Air re-heater - operating message | No | This pin is used to determine the operating state of the air re-heater. |

| Air re-heater - pump operating message | No | This pin is used to determine the operating state of the air re-heater. |

| Air re-heater - valve position | No | This pin is used to determine the operating state of the air re-heater. |

| Air re-heater - valve control signal | No | This pin is used to determine the operating state of the air re-heater. |

Sub-component heat recovery system

| Pin | Required | Mapping info |

|---|---|---|

| Heat recovery system - operating message | No | This pin is used to determine the multi-state of the heat recovery system. |

| Heat recovery system - position | No | This pin is used to determine the multi-state of the heat recovery system. |

| Heat recovery system - control signal | No | This pin is used to determine the multi-state of the heat recovery system. |

Sub-component supply humidifier

| Pin | Required | Mapping info |

|---|---|---|

| Supply humidifier - operating message | No | This pin determines the operating state of the supply humidifier. |

Sub-component exhaust humidifier

| Pin | Required | Mapping info |

|---|---|---|

| Exhaust humidifier - operating message | No | This pin determines the operating state of the exhaust humidifier. |

Sub-component recirculation damper

| Pin | Required | Mapping info |

|---|---|---|

| Recirculation damper - position | No | This pin is used to determine the multi-state of the recirculation damper. |

| Recirculation damper - control signal | No | This pin is used to determine the multi-state of the recirculation damper. |

Sub-component decentralized air cooler

| Pin | Required | Mapping info |

|---|---|---|

| Air cooler - pump operating message | No | This pin is used to determine the operating state of the air cooler. |

| Air cooler - operating message | No | This pin is used to determine the operating state of the air cooler. |

| Air cooler - valve position | No | This pin is used to determine the operating state of the air cooler. |

| Air cooler - inlet temperature | No | This pin is used together with outlet temperature to determine the operating state of the air cooler. |

| Air cooler - outlet temperature | No | This pin is used together with inlet temperature to determine the operating state of the air cooler. |

Sub-component decentralized air heater

| Pin | Required | Mapping info |

|---|---|---|

| Air heater - pump operating message | No | This pin is used to determine the operating state of the air heater. |

| Air heater - operating message | No | This pin is used to determine the operating state of the air heater. |

| Air heater - valve position | No | This pin is used to determine the operating state of the air heater. |

| Air heater - inlet temperature | No | This pin is used together with outlet temperature to determine the operating state of the air heater. |

| Air heater - outlet temperature | No | This pin is used together with inlet temperature to determine the operating state of the air heater. |

Recommend Time Span

1 day to 1 week

- Analysis is useful for all days with system operation

Recommended Repetition

Every month

- After changes of operational modes, e.g., transfers to heating mode

- After changes in the control system of the ventilation systems

- After maintenance or replacements in ventilation systems

Dew Point Alert¶

Building automation systems often have dew point alert messages which identify the possibility of unwanted condensation taking place in rooms. If the dew point alert message is active for any amount of time during the period of analysis, a recommendation is made to the user since rooms condensation in rooms can be damaging. Furthermore, if the temperature and relative humidity of the room are known, the Dew Point Alert analysis calculates the risk of condensation and takes these into account in the evaluation. The Dew Point Alert analysis is recommended for any room with an existing dew point alert signal or with temperature and relative humidity sensors.

Value

- Avoids damage to rooms due to condensation

Recommended for components

- Rooms

Checked conditions

- Duration of dew point alert signal

- Duration in which the room temperature is between 2 °C and 4 °C above the dew point temperature

- Duration in which the room temperature is within 2 °C of the dew point temperature

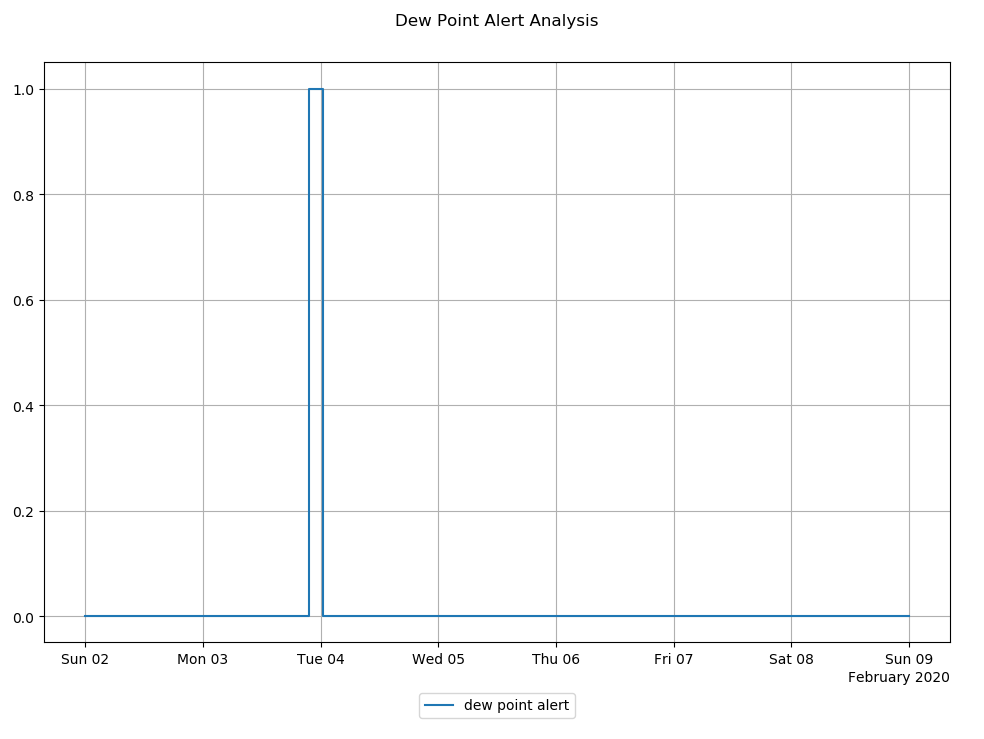

The Dew Point Alert analysis was performed on a room for a week in February 2020. For this particular room, a dew point alert message is available but no temperature and relative humidity data. As is shown in figure 1, the dew point alert signal is only active for a very short amount of time during the week.

Figure 1: Dew point alert for one week in February 2020

The analysis returns a red warning message to indicate that the dew point alert was active during a portion of the time period. This suggests that the condensation may have formed in the room. Note that only "dew point alert" KPIs are generated since no temperature and humidity data are available in this example.

| KPI | Value | Unit |

|---|---|---|

| dew point alert message.relative | 1.69 | % |

| dew point alert message.duration | 2.83 | h |

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | Yes | Dew point alert message is active for some time or the temperature and humidity show a high chance of condensation. |

| yellow | Yes | There is a moderate chance of condensation taking place in the room. |

| green | Yes | Dew point alert message is not active during analysis period. No risk of condensation. |

Interpretations

| Available | Info |

|---|---|

| Yes | Interpretations summarize the result of the analysis. |

Recommendations

| Available | Info |

|---|---|

| Yes | Check the room for condensation and mold. |

KPIs

The KPIs which are generated by this analysis depend on the information available in the analysis. The "dew point alert message" KPIs are generated if a dew point alert message is available. The condensation risk KPIs are generated using room temperature and relative humidity.

The condensation risk is evaluated as moderate if the room temperature is between 2 K and 4 K above the dew point temperature. A high condensation risk is when the room temperature is within 2 K of the dew point temperature.

Dew point alert

| KPI Identifier | Info | Value Range | Unit |

|---|---|---|---|

| dew point alert message.relative | Time of active dew point alert message as a percentage of total time. | 0 to 100 | % |

| dew point alert message.duration | Total time of active dew point alert message. | 0 to inf | h |

| condensation risk moderate.relative | Time of moderate condensation risk as a percentage of total time. | 0 to 100 | % |

| condensation risk moderate.duration | Total time of moderate condensation risk. | 0 to inf | h |

| condensation risk high.relative | Time of high condensation risk as a percentage of total time. | 0 to 100 | % |

| condensation risk high.duration | Total time of high condensation risk. | 0 to inf | h |

| Pin | Required | Mapping info |

|---|---|---|

| Dew point alert message | No | The dew point alert message can be used as the only pin or in combination with temperature and humidity. |

| Temperature | No | If the temperature is mapped, humidity must also be mapped. Can be used in combination with the dew point alert message. |

| Humidity | No | If humidity is mapped, the temperature must also be mapped. Can be used in combination with the dew point alert message. |

Recommend Time Span

1 week to 1 month

Recommended Repetition

Every month

- After changes of operational modes, e.g., transfers to heating mode

- After changes in the control system

- After maintenance and replacement

Dynamic Control¶

The Dynamic Control analysis evaluates whether a technical component is controlled dynamically. This helps to identify problems with control and ensures that components are implemented more energy efficiently.

Value

- Detect AHU fans that are not controlled

- Reduce costs through better fan speed control

Recommended for components

- Air handling unit

- Fan

Checked conditions

- Stationary fan speed

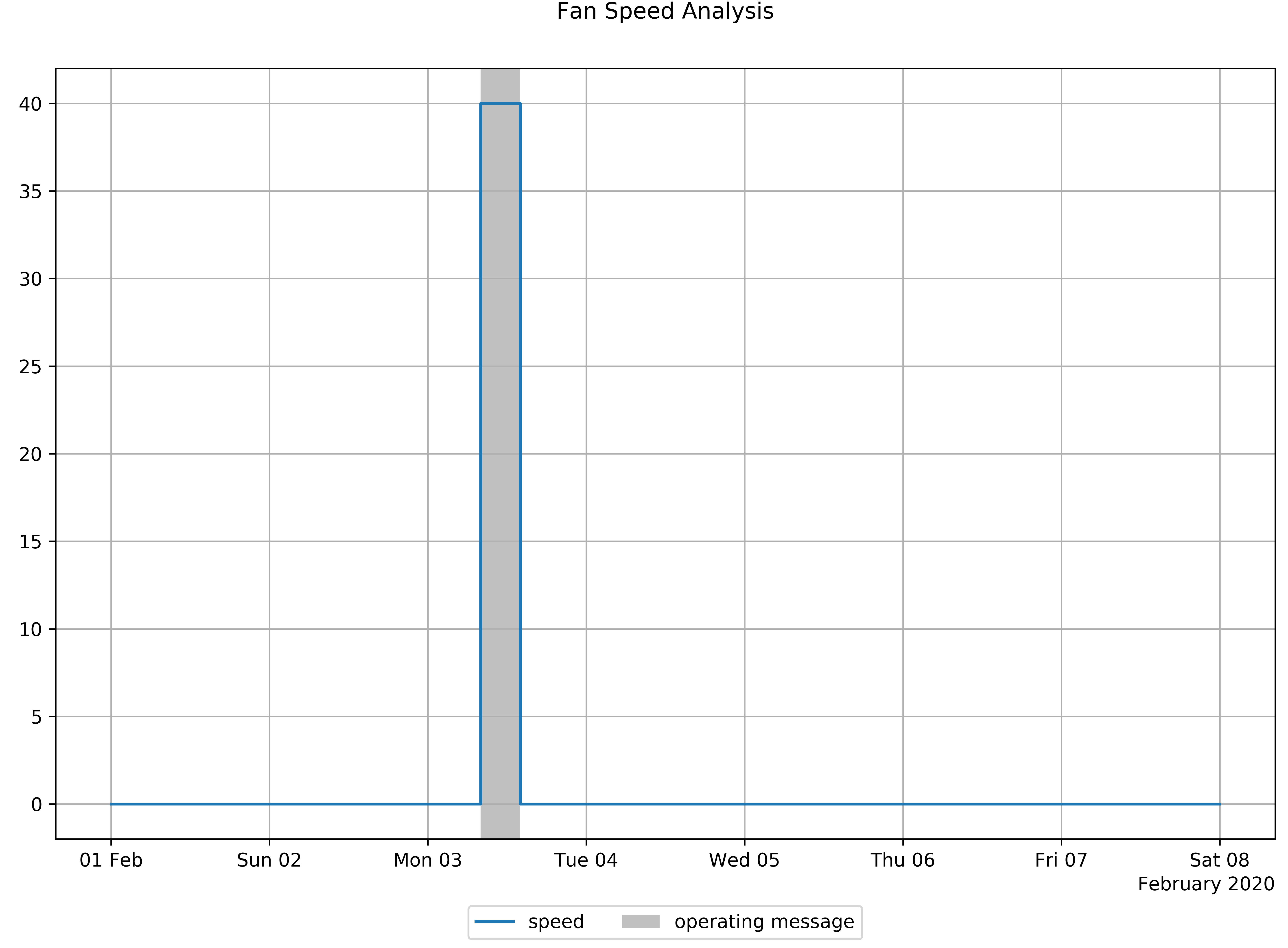

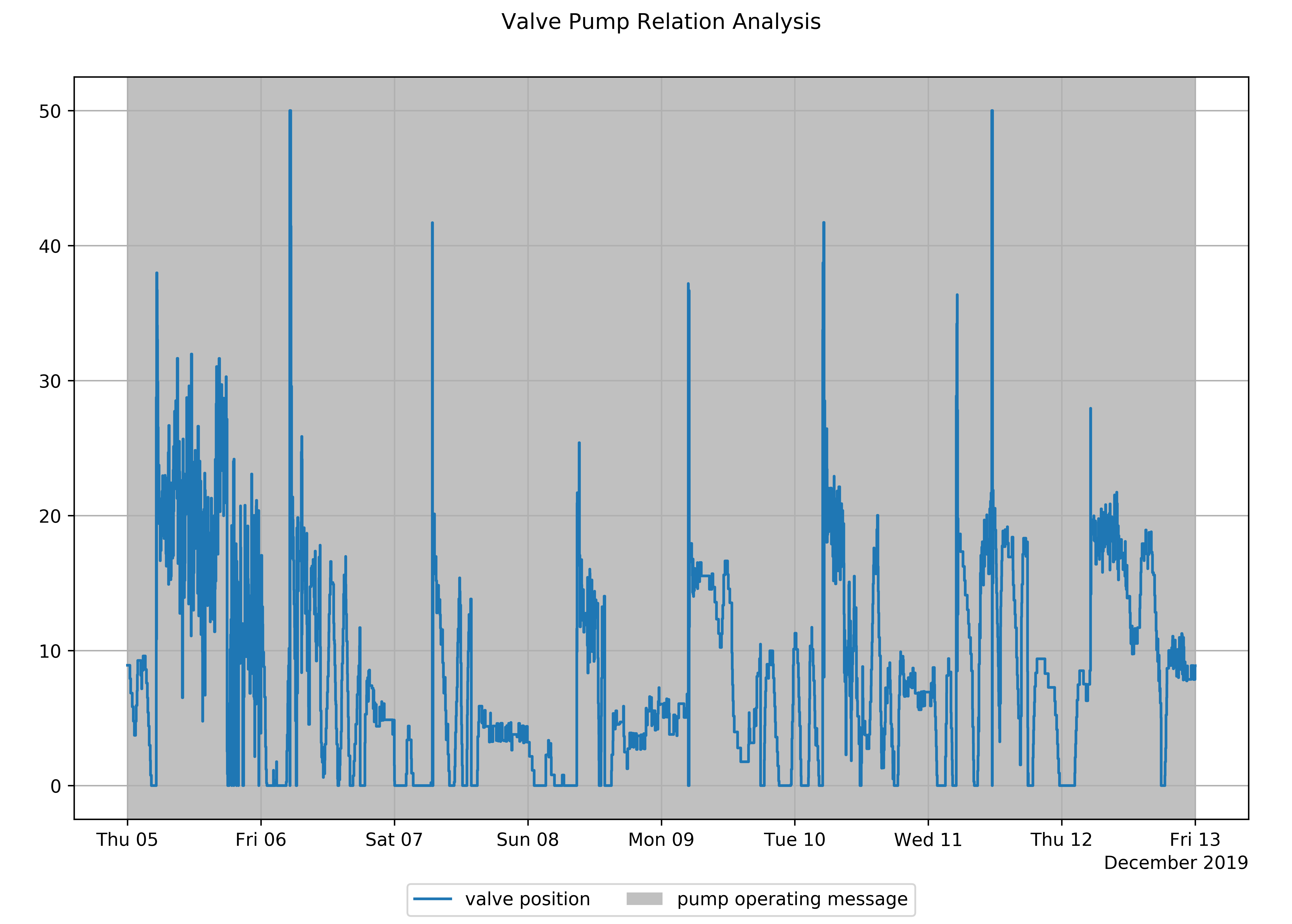

In this example, we look at a Dynamic Control analysis of the historic 7-day fan speed. While the operating message (grey in the plot below) shows the times when the fan was operated, the fan speed (blue in the plot below) corresponds to the speed or load setting of the fan.

Figure 1: Speed and operating message of a 7-day fan speed analysis

From the analysis results, we can see that the fan was operated for 6 hours out of the 168 hours of the week or 3.57 % of the week. Additionally, we get statistics of the fan speed, e.g., the fan was operated at an average of 40 % load.

This corresponds to a static fan speed setting that is currently not controlled. To improve energy efficiency and thermal comfort you can consider different control strategies outlined in the recommendations.

KPI - Statistics

| KPI | Value | Unit |

|---|---|---|

| operating time | 6 | h |

| operating time.relative | 3.57 | % |

| speed.maximum | 40 | % |

| speed.minimum | 40 | % |

| speed.mean | 40 | % |

| speed.median | 40 | % |

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | No | - |

| yellow | Yes | Fan speed is not controlled. |

| green | Yes | Fan speed is controlled. |

Interpretations

| Available | Info |

|---|---|

| Yes | Information about how the fan speed is controlled. |

Recommendations

| Available | Info |

|---|---|

| Yes | Recommendations to look into the different control options for this fan to save energy. |

KPIs

Statistics

statistics for "speed" will be calculated for all measured values that are not 0 %

| KPI Identifier | Info | Value Range | Unit |

|---|---|---|---|

| operating time | Total time where the fan speed is greater than zero | 0 to inf | h |

| operating time.relative | Time where the fan speed is greater than zero relative to the analysis period | 0 to 100 | % |

| speed.maximum | Largest observation recorded of fan speed during analysis period | 0 to 100 | % |

| speed.minimum | Smallest observation recorded of fan speed during analysis period | 0 to 100 | % |

| speed.mean | Time-weighted average of fan speed | 0 to 100 | % |

| speed.median | Time-weighted median of fan speed | 0 to 100 | % |

| Pin | Required | Mapping info |

|---|---|---|

| Exhaust fan - speed | No | Both or just one fan can be connected for this analysis function to work. |

| Supply fan - speed | No | Both or just one fan can be connected for this analysis function to work. |

| Pin | Required | Mapping info |

|---|---|---|

| Speed | Yes | Use this pin to connect the datapoint that reflects fan speed settings from 0 - 100 % load. |

Recommended Time Span

1 week

Recommended Repetition

Every month

Elevators Operating Time Analysis¶

The Elevators Operating Time analysis aggregates all operating states of elevators and calculates total operating time and overall availability. All elevators in one project will be taken into account with this analysis. The analysis is based on aedifion operating states.

Value

- Insights into the operating times of elevators over weekdays

- Insight into the total availability of elevators

Recommended for components

Buildings with elevators

Checked conditions for operating time calculation

| Operating status | Counts as operating time |

|---|---|

| 301 | No |

| 300 | No |

| 200 | No |

| 103 | No |

| 102 | No |

| 101 | No |

| 100 | Yes |

| 0 | No |

Checked conditions for availability calculation

| Operating status | Counts as not-available |

|---|---|

| 301 | Yes |

| 300 | Yes |

| 200 | No |

| 103 | No |

| 102 | No |

| 101 | No |

| 100 | No |

| 0 | No |

An analysis on a building with elevators is carried out for an analysis period of 3 weeks.

KPI - Statistics

| KPI | Value | Unit |

|---|---|---|

| elevators availability | 94.1 | % |

Bar chart Average Elevators Operating Time

| Data | Value | Unit |

|---|---|---|

| Monday | 2.5 | h |

| Tuesday | 5.0 | h |

| Wednesday | 7.5 | h |

| Thursday | 60.0 | h |

| Friday | 60.0 | h |

| Saturday | 0.0 | h |

| Sunday | 13.75 | h |

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | Yes | Availability <= 80 % |

| yellow | Yes | Availability > 80 % |

| green | Yes | Availability > 95 % |

Interpretations

| Available | Info |

|---|---|

| Yes | Interpretations summarize the result of the analysis. |

Recommendations

| Available | Info |

|---|---|

| Yes | Info text and recommendation for action. |

KPIs

Summary KPI

| KPI reference | Info | Value Range | Unit |

|---|---|---|---|

| elevators availability | Aggregated availability for analysis period | 0 - 100 | % |

Plots

| Identifier | Type | Info | Unit |

|---|---|---|---|

| elevator_operating_time | bar_chart | Average elevators operating time over weekdays | h |

| Pin | Required | Mapping info | Unit |

|---|---|---|---|

| - | - | - | - |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| - | - | - | - |

Sub-components

At least one sub-component is needed to get a result for this analysis function.

| Pin | Required | Mapping info |

|---|---|---|

| Operational state | Yes | Operational state with aedifion states |

Recommend Time Span

1 week

Recommended Repetition

weekly

- Continuously monitor availability of elevators

- Track operating times of your elevators

Energy Consumption¶

The Energy Consumption analysis aggregates all energy consumptions indicated by the meter components in the building during the analysis period. The total energy consumption is related to the net floor area of the building and is benchmarked against the usual consumption of the same type of building.

Value

- ESG-Reporting and monitoring of energy consumption

- Insights into the energy consumption of the building

- Energy consumption benchmarking

- Trace back consumption to the energy source

Recommended for components

Complete buildings or energy systems

Checked conditions

- Energy consumption of the building or system

- Benchmarking

- Energy consumption by energy source

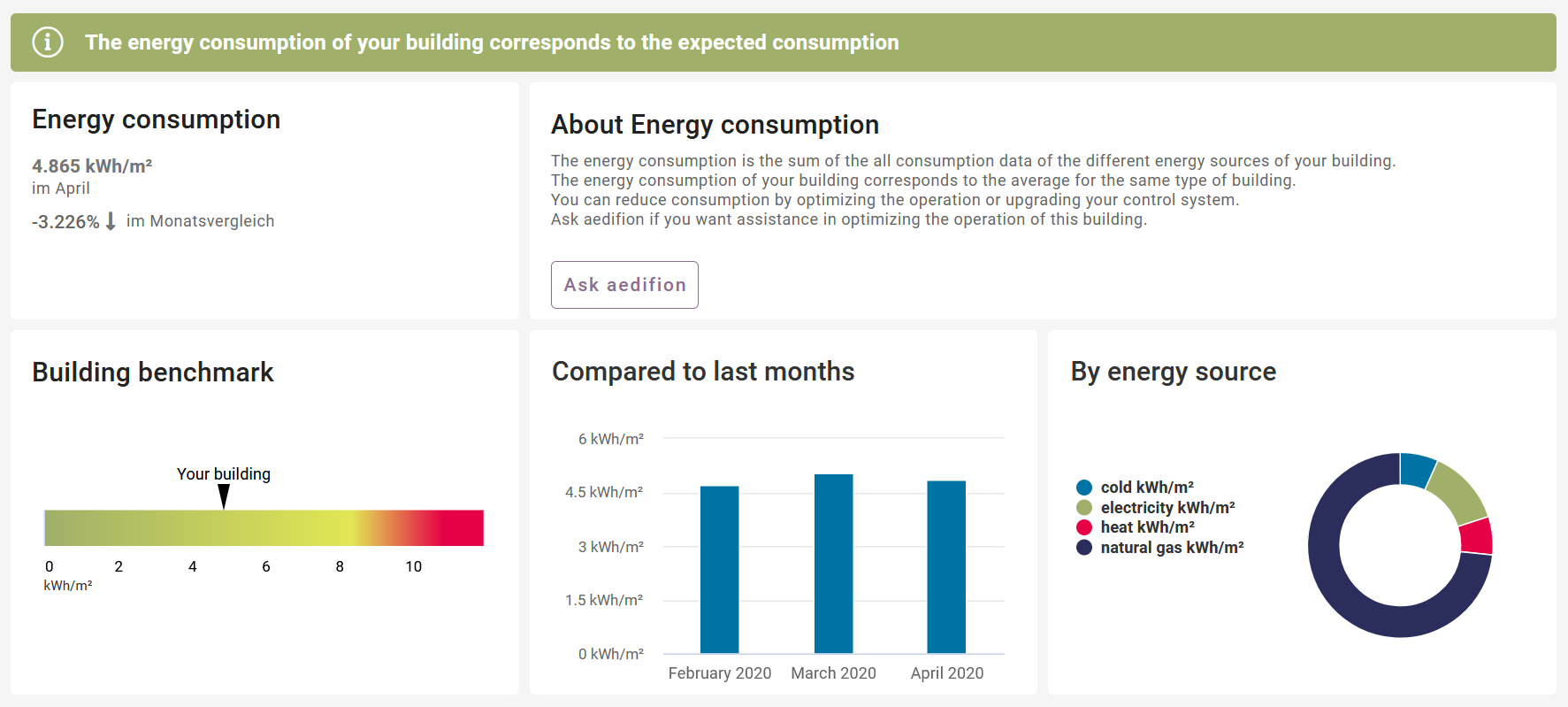

This example shows the results of an Energy Consumption analysis displayed in the Asset Overview.

Figure 1: Energy Consumption Asset Overview result overview

Above all cards the interpretation text of the result is highlighted with the signal color of the result. In the top left the current KPI and the monthly trend is shown. On the right side of that you will find the recommendations of this result as well as further information about the function.

The three plots below are:

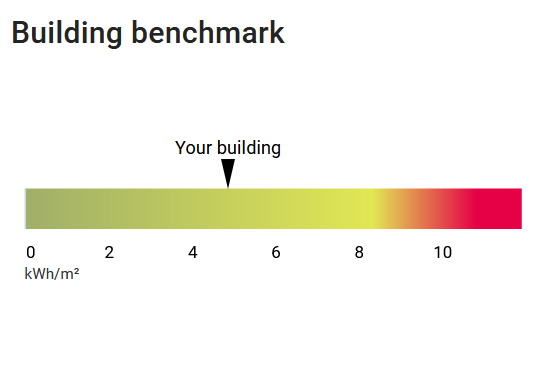

- The building benchmark

Figure 2: Energy Consumption Asset Overview plot bullet graph

The current energy consumption is plotted inside a bullet graph between the limits of the signal color.

- Compared to last months

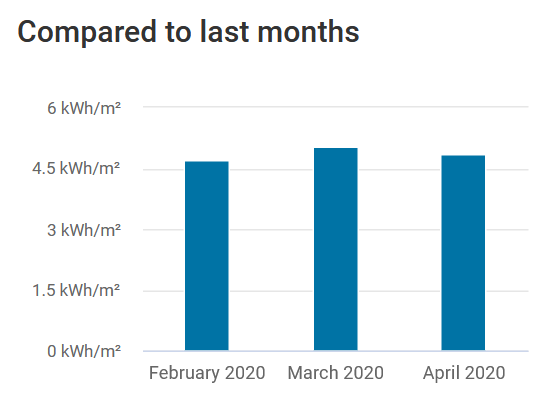

Figure 3: Energy Consumption Asset Overview plot month comparison

The plot shows the energy consumption of the last three months, including the month of the analysis.

- By energy source

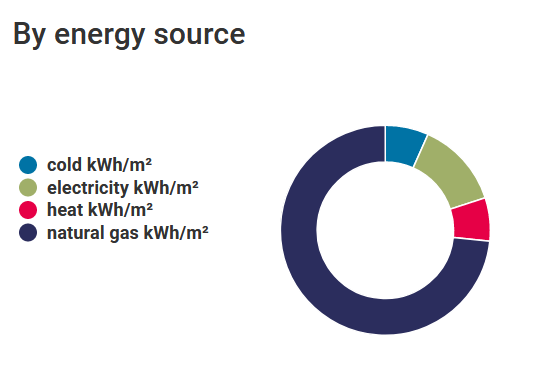

Figure 4: Energy Consumption Asset Overview plot energy source

The plot shows the distribution of energy consumption by energy source.

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | Yes | Energy consumption significantly above average for this type of building. |

| yellow | Yes | Energy consumption significantly above average for this type of building. |

| green | Yes | Energy consumption below average for this type of building. |

Interpretations

| Available | Info |

|---|---|

| Yes | Interpretations summarize the result of the analysis. |

Recommendations

| Available | Info |

|---|---|

| Yes | Info text and recommendation for action. |

KPIs

Summary KPI

| KPI reference | Info | Value Range | Unit |

|---|---|---|---|

| current | Aggregated energy consumption during analysis period | -inf to inf | kWh/m2/M |

| development | Change in energy consumption compared to last analysis period | -inf to inf | % |

Timeseries

The timeseries is saved as a virtual datapoint. Every run of the analysis will add the summary KPI (current value) as an observation at the start of the analysis period to the timeseries.

| Timeseries datapointID | Info | Unit |

|---|---|---|

| {project_id}_{instance_id}_energy_consumption_absolute | Absolute energy consumption timeseries | kWh |

| {project_id}_{instance_id}_energy_consumption | Specific energy consumption timeseries | kWh/m2/M |

Plots

| Identifier | Type | Info | Unit |

|---|---|---|---|

| benchmark | bullet_graph | Energy consumption benchmarking including color scale | kWh/m2/M |

| month_comparison | bar_chart | Energy consumption of the last 3 months | kWh/m2/M |

| energy_consumption | pie_chart | Energy consumption by energy source | % |

| Pin | Required | Mapping info | Unit |

|---|---|---|---|

| - | - | - | - |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Energy consumption limit red | No | Overwrite the red limit for the energy consumption KPI for this building | kWh/m2/M |

| Energy consumption limit yellow | No | Overwrite the yellow limit for the energy consumption KPI for this building | kWh/m2/M |

| Net floor area | Yes | Used to calculate the per area KPI for current value | m2 |

Sub-components

At least one sub-component is needed to get a result for this analysis function. Only the necessary meter components need to be added to the project.

| Pin | Required | Mapping info |

|---|---|---|

| Cooling energy | Yes | Cumulating timeseries in kWh |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

| Pin | Required | Mapping info |

|---|---|---|

| Active energy | Yes | Cumulating timeseries in kWh |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

| Pin | Required | Mapping info |

|---|---|---|

| Gas quantity | Yes | Cumulating timeseries in m3 |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Calorific value of natural gas | No | Change to calorific value of delivered natural gas. Default: 13 kWh/m3 | kWh/m3 |

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

| Pressure compensation factor of natural gas | No | Additional factor to compensate for elevation and line pressure at the termination point. Default: 1 |

| Pin | Required | Mapping info |

|---|---|---|

| Heating energy | Yes | Cumulating timeseries in kWh |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

Recommend Time Span

1 month

Recommended Repetition

Monthly

- Continuously monitor energy costs

- Track success of a energy savings measure

Energy Cost¶

The Energy Cost analysis aggregates all energy costs indicated by the meter components in the building during the analysis period. The energy costs are related to the net floor area of the building and are benchmarked against the usual costs of the same type of building.

Value

- ESG-Reporting and monitoring of energy costs

- Insights into the energy costs of the building

- Energy costs benchmarking

- Trace back costs to the energy source

Recommended for components

Complete buildings or energy systems

Checked conditions

- Energy costs of the building or system

- Benchmarking

- Energy costs by energy source

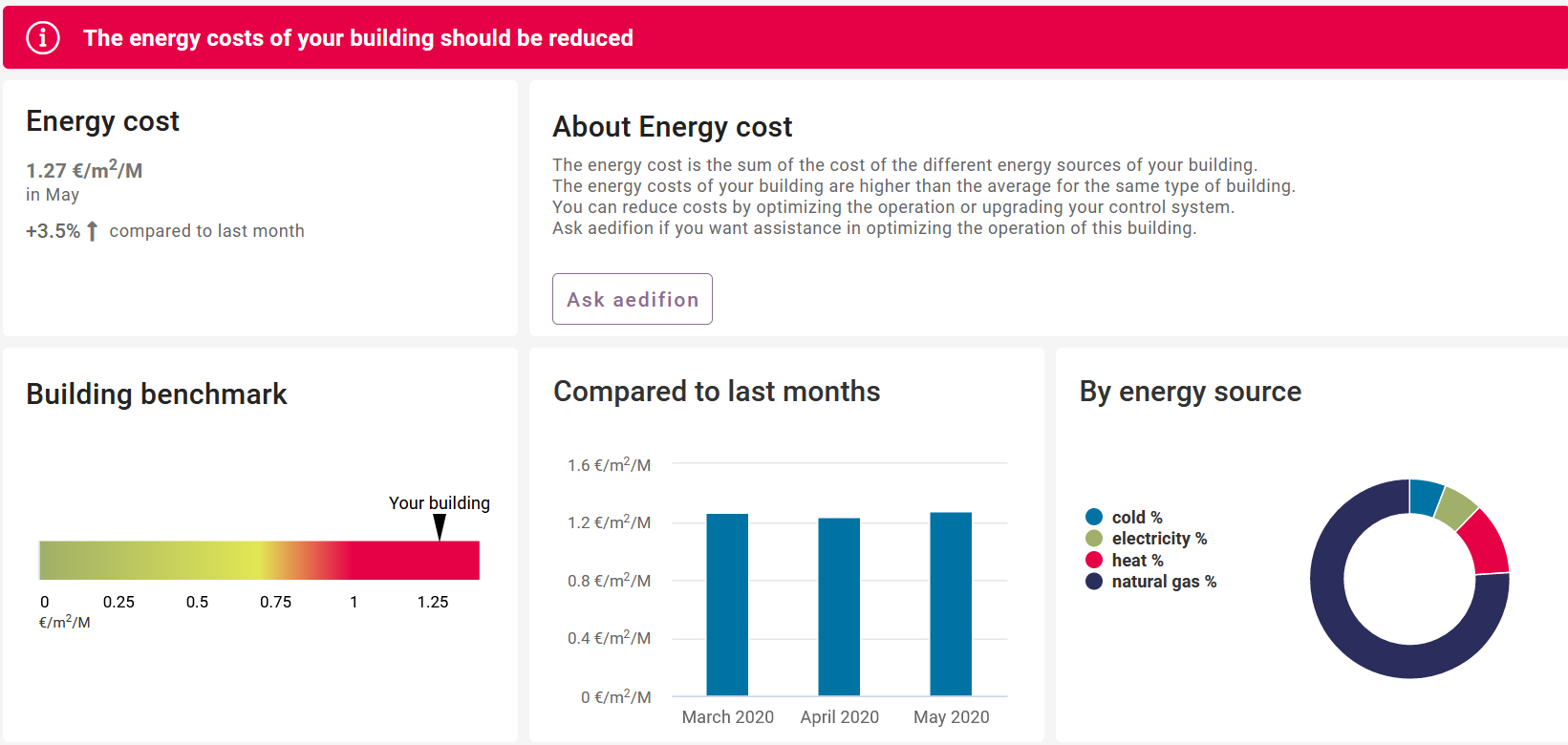

This example shows the results of an Energy Costs analysis displayed in the Asset Overview.

Figure 1: Energy Cost Asset Overview result overview

Above all cards the interpretation text of the result is highlighted with the signal color of the result. In the top left the current KPI and the monthly trend is shown. On the right side of that you will find the recommendations of this result as well as further information about the function.

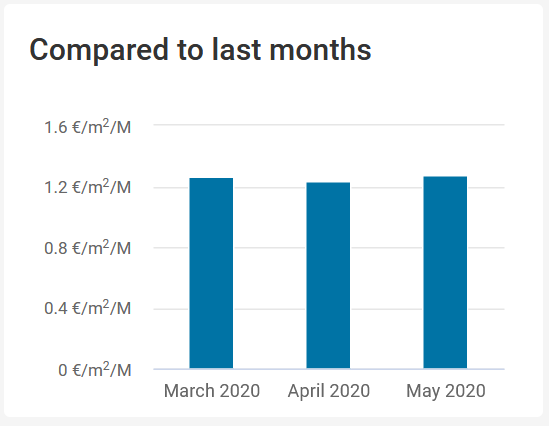

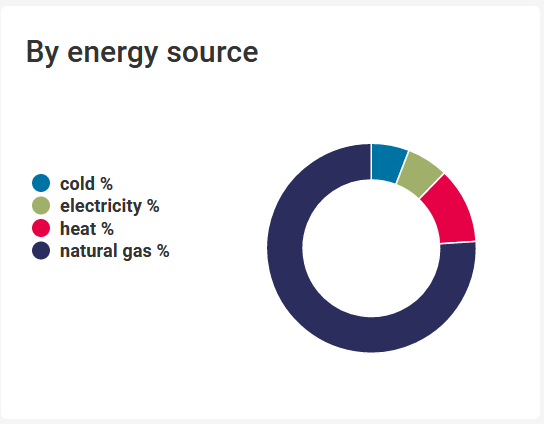

The three plots below are:

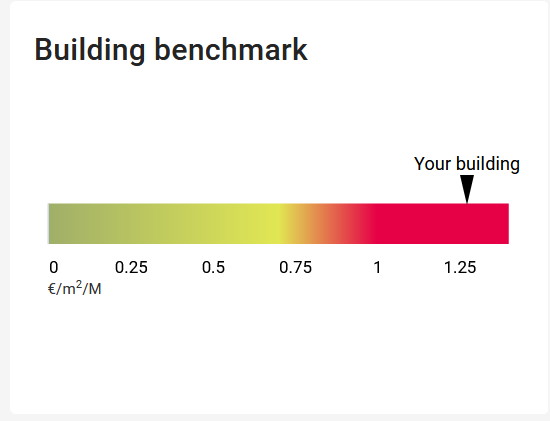

- The building benchmark

Figure 2: Energy Cost Asset Overview plot bullet graph

The current energy cost is plotted inside a bullet graph between the limits of the signal color.

- Compared to last months

Figure 3: Energy Cost Asset Overview plot month comparison

The plot shows the energy costs of the last three months, including the month of the analysis.

- By energy source

Figure 4: Energy Cost Asset Overview plot energy source

The plot shows the distribution of energy costs by energy source.

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | Yes | Energy costs significantly above average for this type of building. |

| yellow | Yes | Energy costs significantly above average for this type of building. |

| green | Yes | Energy costs below average for this type of building. |

Interpretations

| Available | Info |

|---|---|

| Yes | Interpretations summarize the result of the analysis. |

Recommendations

| Available | Info |

|---|---|

| Yes | Info text and recommendation for action. |

KPIs

Summary KPI

| KPI reference | Info | Value Range | Unit |

|---|---|---|---|

| current | Aggregated energy costs during analysis period | -inf to inf | €/m2/M |

| development | Change in energy costs compared to last analysis period | -inf to inf | % |

Timeseries

The timeseries is saved as a virtual datapoint. Every run of the analysis will add the summary KPI (current value) as an observation at the start of the analysis period to the timeseries.

| Timeseries datapointID | Info | Unit |

|---|---|---|

| {project_id}_{instance_id}_energy_cost_absolute | Absolute energy cost timeseries | € |

| {project_id}_{instance_id}_energy_cost | Specific energy cost timeseries | €/m2/M |

Plots

| Identifier | Type | Info | Unit |

|---|---|---|---|

| benchmark | bullet_graph | Energy expenses benchmarking including color scale Default: Based Oscar Report | €/m2/M |

| month_comparison | bar_chart | Energy expenses of the last 3 months | €/m2/M |

| energy_consumption | pie_chart | Energy expenses by energy source | % |

| Pin | Required | Mapping info | Unit |

|---|---|---|---|

| - | - | - | - |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Electricity price | No | Set default price for electricity of this building used for all electricity meters without a set price | €/kWh |

| Energy cost limit red | No | Overwrite the red limit for the energy cost KPI for this building | €/m2/M |

| Energy cost limit yellow | No | Overwrite the yellow limit for the energy cost KPI for this building | €/m2/M |

| Net floor area | Yes | Used to calculate the per area KPI for current value | m2 |

Sub-components

At least one sub-component is needed to get a result for this analysis function. Only the necessary meter components need to be added to the project.

| Pin | Required | Mapping info |

|---|---|---|

| Cold price | No | Specific price for the underlying energy in €/kWh. Alternative for the corresponding attribute. If the attribute is set the pin is not considered inside the analysis. |

| Cooling energy | Yes | Cumulating timeseries in kWh |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Cold price | Yes | Specific price for the underlying energy. If the attribute is set the corresponding pin is not considered inside the analysis. | €/kWh |

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

| Pin | Required | Mapping info |

|---|---|---|

| Active energy | Yes | Cumulating timeseries in kWh |

| Electricity price | No | Specific price for the underlying energy in €/kWh. Alternative for the corresponding attribute. If the attribute is set the pin is not considered inside the analysis. |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

| Electricity price | No | Specific price for the underlying energy. If the attribute is set the corresponding pin is not considered inside the analysis. | €/kWh |

| Pin | Required | Mapping info |

|---|---|---|

| Fuel price | No | Specific price for the underlying energy in €/kWh. Alternative for the corresponding attribute. If the attribute is set the pin is not considered inside the analysis. |

| Gas quantity | Yes | Cumulating timeseries in m3 |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Calorific value of natural gas | No | Change to calorific value of delivered natural gas. Default: 13 kWh/m3 | kWh/m3 |

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

| Fuel price | Yes | Specific price for the underlying energy. If the attribute is set the corresponding pin is not considered inside the analysis. | €/kWh |

| Pressure compensation factor of natural gas | No | Additional factor to compensate for elevation and line pressure at the termination point. Default: 1 |

| Pin | Required | Mapping info |

|---|---|---|

| Heat price | No | Specific price for the underlying energy in €/kWh. Alternative for the corresponding attribute. If the attribute is set the pin is not considered inside the analysis. |

| Heating energy | Yes | Cumulating timeseries in kWh |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Cost measurement device | Yes | Set to 'True' if this component should be considered in this analysis | binary |

| Heat price | Yes | Specific price for the underlying energy. If the attribute is set the corresponding pin is not considered inside the analysis. | €/kWh |

Recommend Time Span

1 month

Recommended Repetition

Monthly

- Continuously monitor energy costs

- Track success of a energy savings measure

Energy Efficiency¶

The Energy Efficiency analysis evaluates the quality of the energy conversion of a component, based on efficiency indicators. It is useful to detect inefficient operational states. Furthermore, information is provided regarding which part of the plant is responsible for the malfunction and what could be done to resolve the problem.

Value

- Reduced operational costs

- Detection of broken components

Recommended for components

- Combined heat and power

Checked conditions

- Efficiency of component

- Power to heat ratio (for component combined heat and power)

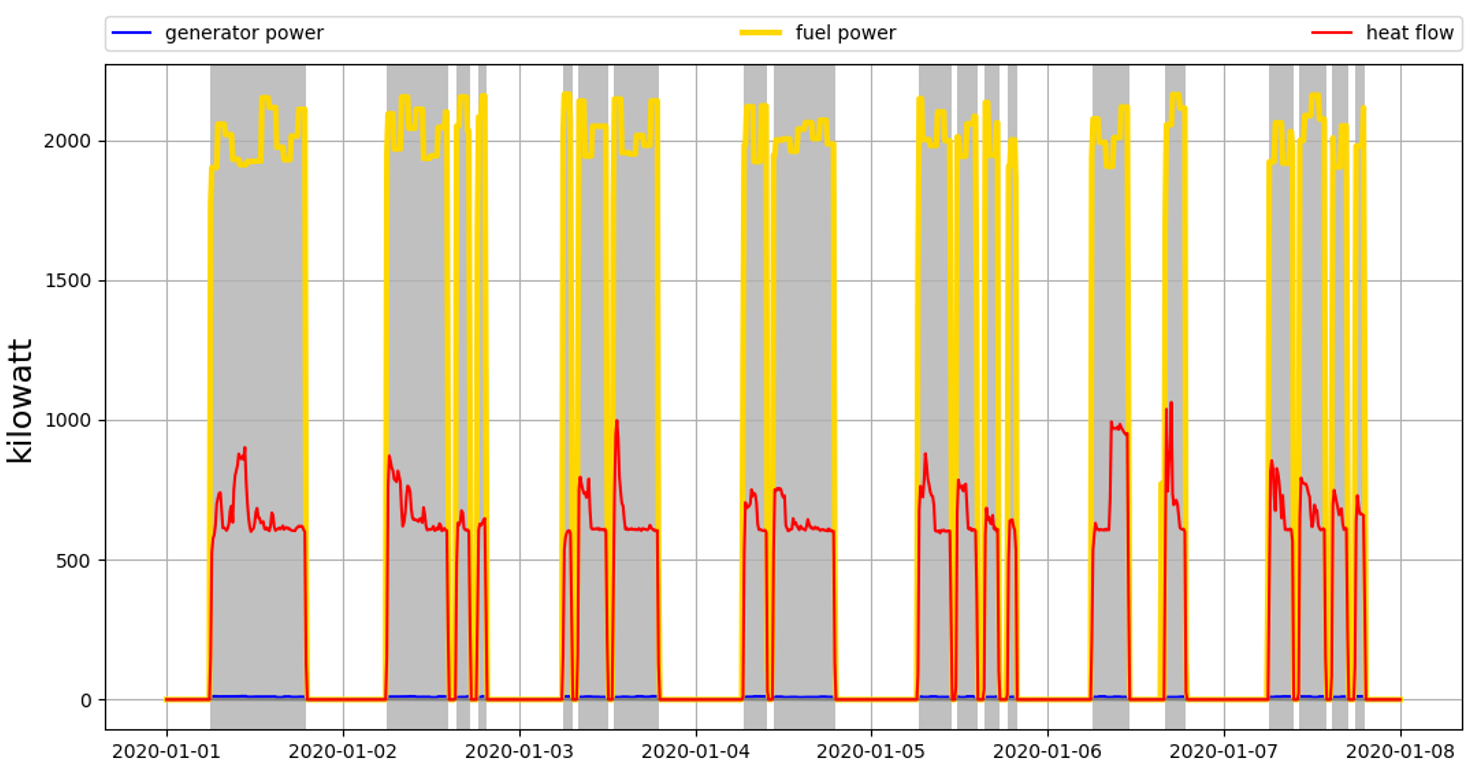

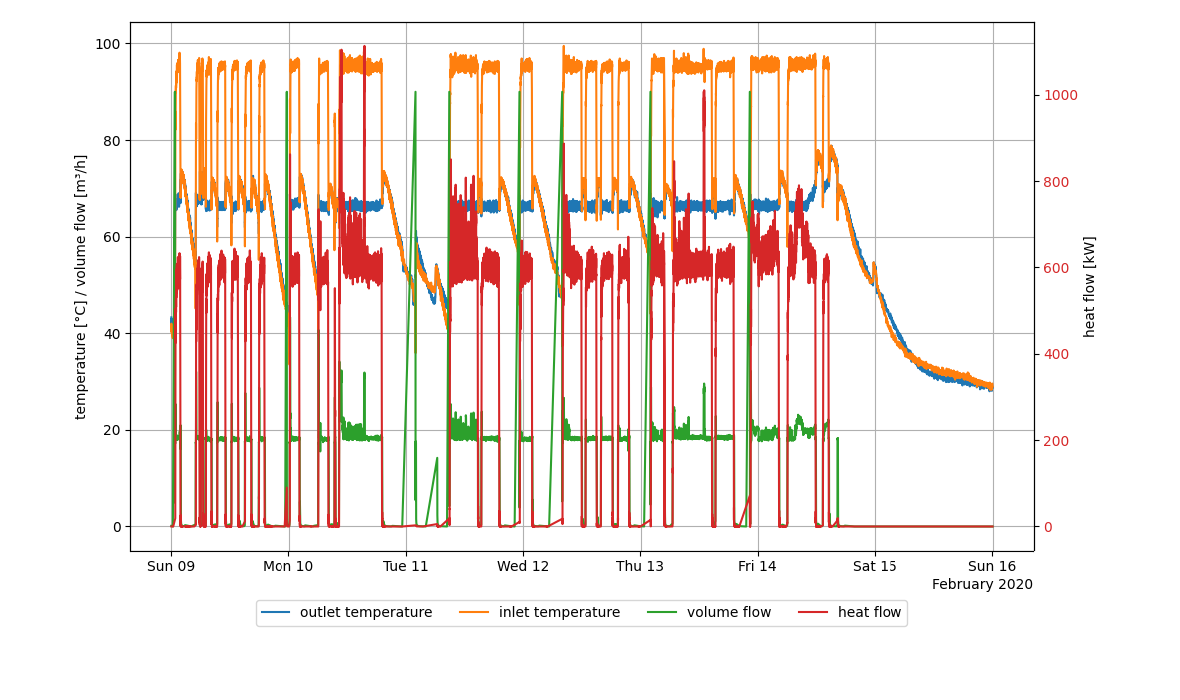

The Energy Efficiency analysis was applied to a real combined heat and power plant and the pins operating message, generator power, heat flow, and fuel power were mapped. Figure 1 shows the time series recorded for an exemplary period of 7 days. The grey shaded periods correspond to the operation of the plant.

Figure 1: Period of one week for which the energy conversion is not acceptable

A very low generator power compared to the heat flow and the fuel power indicates a failure of the generator component. The automated interpretation confirms our visual analysis of the time series shown in the figure, summed up by the qualitative warning level “red”. It also provides recommendations to address the problem.

| KPI | Value | Unit |

|---|---|---|

| generator power.mean | 9.4 | kW |

| heat flow.mean | 640.9 | kW |

| fuel power.mean | 1940.3 | kW |

| power to heat ratio | 1.47 | % |

| fuel utilization factor | 33.5 | % |

| thermal efficiency | 33.0 | % |

| electric efficiency | 0.485 | % |

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | Yes | The quality of the energy conversion is not acceptable. |

| yellow | Yes | The quality of the energy conversion is suboptimal. |

| green | Yes | The quality of the energy conversion is good. |

Interpretations

| Available | Info |

|---|---|

| Yes | Interpretations summarize the result of the analysis. |

Recommendations

| Available | Info |

|---|---|

| Yes | Recommendations to improve energy conversion. No recommendation, in case of good energy conversion. |

KPIs

Energy Performance KPIs

| KPI Identifier | Info | Value Range | Unit |

|---|---|---|---|

| generator power.mean | Average generator power | 0 to inf | kW |

| fuel power.mean | Average fuel power | 0 to inf | kW |

| power to heat ratio | Cumulated electrical energy divided by the cumulated heat energy | 0 to inf | % |

| fuel utilization factor | Total efficiency of the plant (i.e., total heat and power divided by total energy provided by the fuel energy) | 0 to 100 | % |

| thermal efficiency | Cumulated heat energy divided by the total fuel energy | 0 to 100 | % |

| electrical efficiency | Cumulated electrical energy divided by the total fuel energy | 0 to 100 | % |

| Pin | Required | Mapping info |

|---|---|---|

| Operating message | No | - |

| Generator power | Yes | - |

| Heat flow | Yes | - |

| Rate of fuel consumption | No | - |

| Attribute | Required | Mapping info |

|---|---|---|

| Fuel price | No | Default: 0.06 €/kWh Gas |

| Electricity price | No | Default: 0.18€/kWh |

| Heat price | No | Default: 0.065 €/kWh |

| Generator nominal power | No | - |

| Nominal heat production | No | - |

Recommended Time Span

1 day to 1 week

Recommended Repetition

Every month

Filter Servicing¶

The Filter Servicing analysis predicts when a filter is due to be serviced or replaced, based on filter contamination or the pressure difference over the filter. This ensures that filters always function optimally and are maintained or replaced as required.

Value

- Ensures filter is serviced when required

- Improves energy efficiency

Recommended for components

- Filter

Checked conditions

- Filter contamination

- Expected time till filter service or replacement

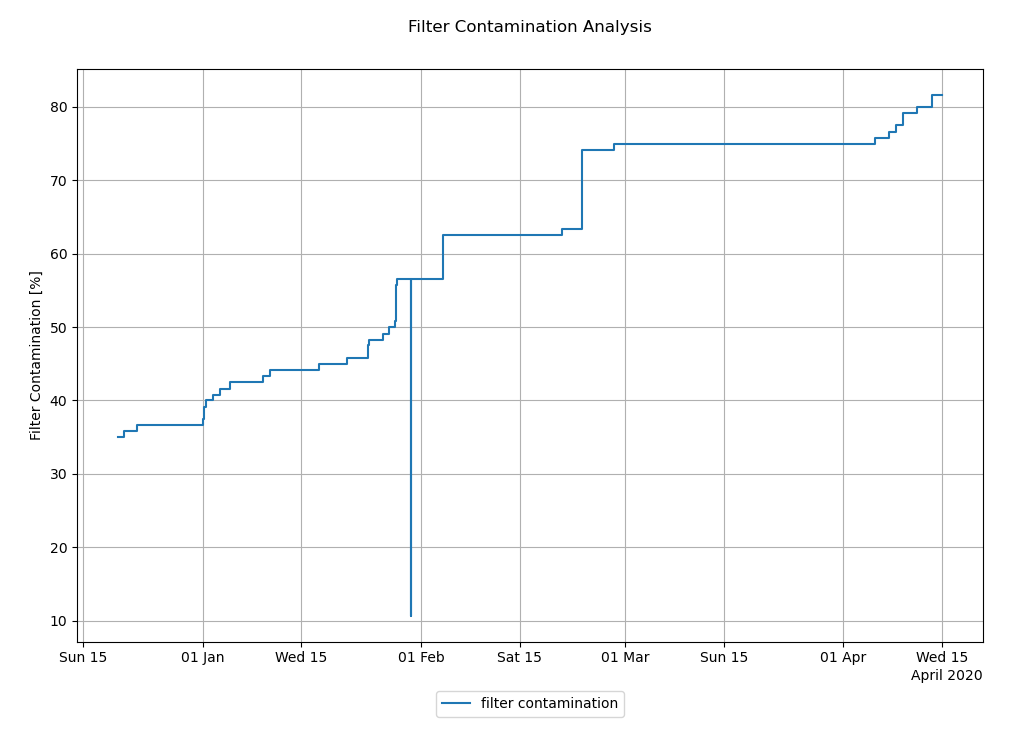

In this example, the filter contamination of an exhaust air filter of an air handling unit was analyzed over a period of four months. As can be seen in figure 1, filter contamination gradually increases over the analyzed period.

Figure 1: Filter contamination over a four month period

The signal analysis returns a green signal color since there is a significant amount of time before the filter is fully contaminated.

| KPI | Value | Unit |

|---|---|---|

| days until filter service | 35 | d |

| expected date of filter service | 2020-05-20 | date |

| filter contamination | 79.3 | % |

Signal colors

| Signal color | Available | Info |

|---|---|---|

| red | No | - |

| yellow | Yes | The filter is almost contaminated, a filter service should scheduled. |

| green | Yes | The filter is in a good condition and does not need to be serviced. |

Interpretations

| Available | Info |

|---|---|

| Yes | Information regarding the filter condition and whether the filter needs to be serviced. |

Recommendations

| Available | Info |

|---|---|

| Yes | Make necessary arrangements for the filter to be serviced. No recommendation if the filter does not need servicing within two weeks and the filter contamination is below 95%. |

KPIs

| KPI Identifier | Info | Value Range | Unit |

|---|---|---|---|

| days until filter service | Number of days until filter expected filter service | 0 to inf | d |

| expected date of filter service | Date on which filter is expected to require a service (format: YYYY-MM-DD) | - | date |

| filter contamination | Relative extent to which filter is contaminated | 0 to 100 | % |

| Pin | Required | Mapping info |

|---|---|---|

| Filter contamination | No | Either filter contamination (preferred) or pressure difference must be mapped. If both pins are mapped, filter contamination is used. |

| Pressure difference | No | Either filter contamination (preferred) or pressure difference must be mapped. If both pins are mapped, filter contamination is used. |

| Attribute | Required | Mapping info |

|---|---|---|

| Filter class | No | Default: F9 |

| Initial pressure difference | No | Default: initial pressure difference of filter class (50 Pa for filter class F9), setting this attribute is recommended. |

| Final pressure difference | No | Default: final pressure difference of filter class (300 Pa for filter class F9), setting this attribute is highly recommended. |

Recommended Time Span

1 month to 6 months

Recommended Repetition

Twice a month

Flexible Tariff¶

The Flexible Tariff analysis determines the potential electricity cost savings of a flexible electricity tariff compared to a fixed electricity tariff. The analysis evaluates the potential savings based on the electricity consumption profile during the analysis period. Therefore, the potential is evaluated purely through a tariff change without any assumption about the flexibility of the consumption profile. The flexible electricity tariff consists of a static and a dynamic part. The static part is defined by the attribute static part of the flexible electricity tariff of the component electricity meter. The dynamic part is defined by the datapoint price-service-forecast-0h-day-ahead-electricity-price-smard. The fixed electricity tariff is defined by the attribute electricity price or alternatively by the pin electricity price and assumed to be the tariff currently applicable to the electricity meter. The saving potential is the difference between the actual electricity costs and the costs of a flexible tariff.

Value

- Calculation of the electricity costs if a flexible tariff had been used

- Comparison to the actual electricity costs and identification of a savings potential

- Indication if a flexible tariff would be economically beneficial based on the consumption profile in the analysis period

Recommended for components

- Electricity meter

Checked conditions

- Checks whether or not the use of a flexible tariff would have reduced costs

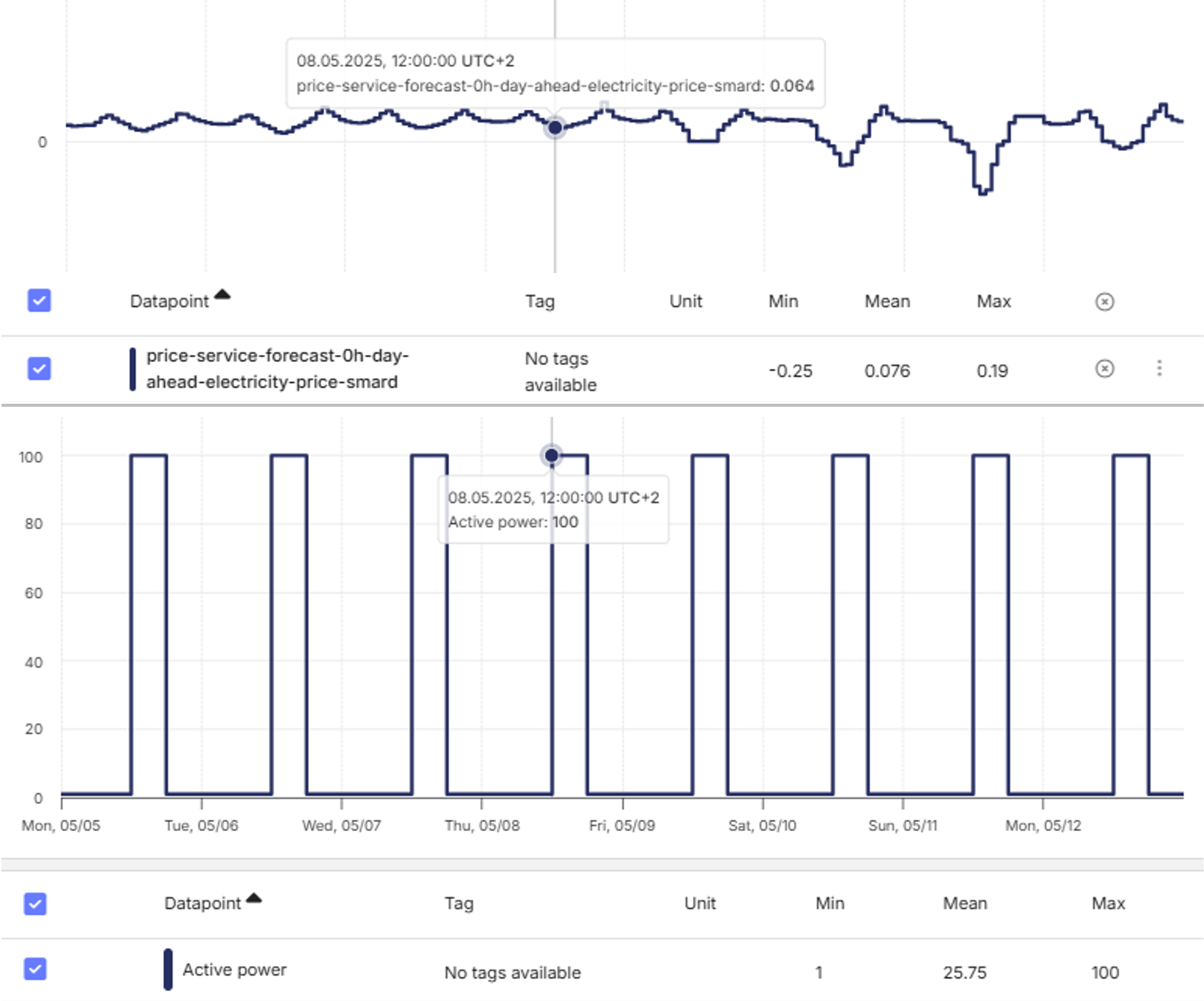

Figure 1 shows a scenario in which energy consumption coincides with relatively low electricity prices. In this example, the current fixed electricity price is 0.3 €/kWh. The static part of the flexible tariff is 0.2 €/kWh and the dynamic part is defined by the datapoint price-service-forecast-0h-day-ahead-electricity-price-smard.

In this scenario, a flexible tariff would have saved 27.37 % of the costs compared to the costs with the current fixed tariff. Hence, the analysis returns a red signal color and a recommendation to consider a flexible tariff. The following KPIs are calculated:

| KPI | Value | Unit |

|---|---|---|

| Electrical energy | 4326 | kWh |

| Energy cost | 1298 | € |

| Energy cost.flexible tariff | 942.6 | € |

| savings potential | 355.2 | € |

| savings potential.relative | 27.37 | % |

Signal colors

To determine the signal color the KPI savings potential.relative is evaluated.

| Signal color | Available | Info |

|---|---|---|

| red | Yes | Savings potential found and the relative saving potential is greater than 10% |

| yellow | Yes | Savings potential found and the relative saving potential is below 10% |

| green | Yes | No savings potential found |

Interpretations

| Available | Info |

|---|---|

| Yes | Information if a saving potential is found or not |

Recommendations

| Available | Info |

|---|---|

| Yes | Recommendation to consider a flexible tariff. In addition, it is indicated if the datapoint price-service-forecast-0h-day-ahead-electricity-price-smard is missing. |

KPIs

| KPI Identifier | Info | Value Range | Unit |

|---|---|---|---|

| Electrical energy | Consumption of electrical energy during the analysis period | 0 to inf | kWh |

| Energy cost | Electricity costs of the current electricity tariff | 0 to inf | € |

| Energy cost.flexible tariff | Electricity costs if a flexible tariff had been used | -inf to inf | € |

| savings potential | Costs savings if a flexible tariff had been used. Equal to the difference between Energy cost and Energy cost.flexible tariff | 0 to inf | € |

| savings potential.relative | Relative cost savings | 0 to 100 | % |

| Pin | Required | Mapping info |

|---|---|---|

| Active energy | No | Candidate #1 for the electricity consumption |

| Active energy consumption values | No | Candidate #2 for the electricity consumption |

| Active power | No | Candidate #3 for the electricity consumption |

| Electricity price | No | The price of the current, fixed tariff needs to be provided by the attribute Electricity price or alternatively by the pin Electricity price |

| Attribute | Required | Mapping info |

|---|---|---|

| Electricity price | No | The price of the current, fixed tariff needs to be provided by the attribute Electricity price or alternatively by the pin Electricity price |

| Static part of the flexible electricity tariff | Yes | Default: 0.2 €/kWh |

In addition, the datapoint price-service-forecast-0h-day-ahead-electricity-price-smard must be available to execute the analysis. This datapoint defines the dynamic part of the flexible electricity tariff.

Recommended Time Span

1 month to 12 months

Recommended Repetition

Every month

Heat Demand¶

The heat demand analysis consolidates all billing-relevant heat energy meters to calculate the total heat demand of the building. The algorithm establishes a correlation between the heat demand and the outside air temperature of the building. The objective is to create a mathematical model that estimates the heat demand based on the outside air temperature. The base load energy, such as water heating, is calculated separately.

The analysis compares the current analysis period with a reference period to calculate energy savings.

Value

- Linear model representing the heat demand of the building

- Determination of a basic heat load e.g. for hot water energy demand

- Determination of a heating limit temperature

- Determination of a maximum heating power within one period

- Determination of zero heating power duration within one period

Recommended for components

Building with gas heating or district heating

Checked conditions

- Heat energy consumption of the building

- Comparison of heat energy consumption between different periods

- Energy saving calculation of reference period to analysis period

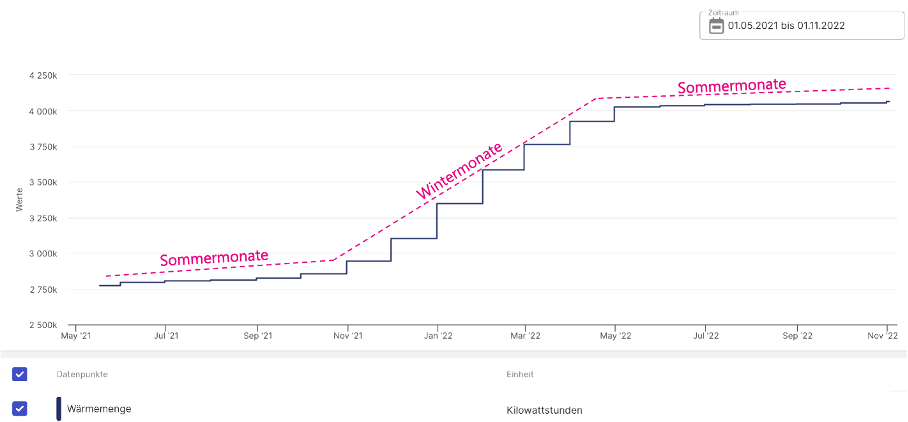

This example shows the monthly sampled heat energy of the main heat meter over the period of more than one year. As shown in Figure 1, a heating period between November and April and a period without required heating were selected.

Figure 1: Heat meter energy samples with monthly resolution

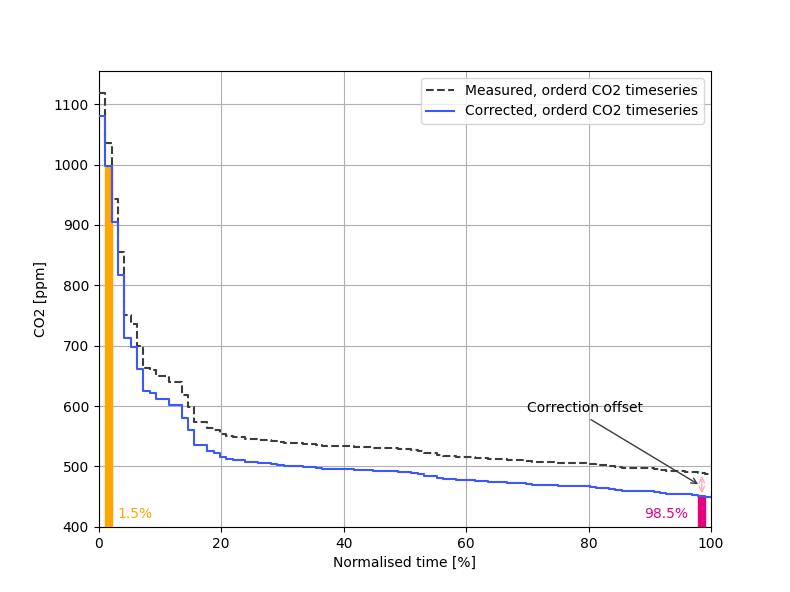

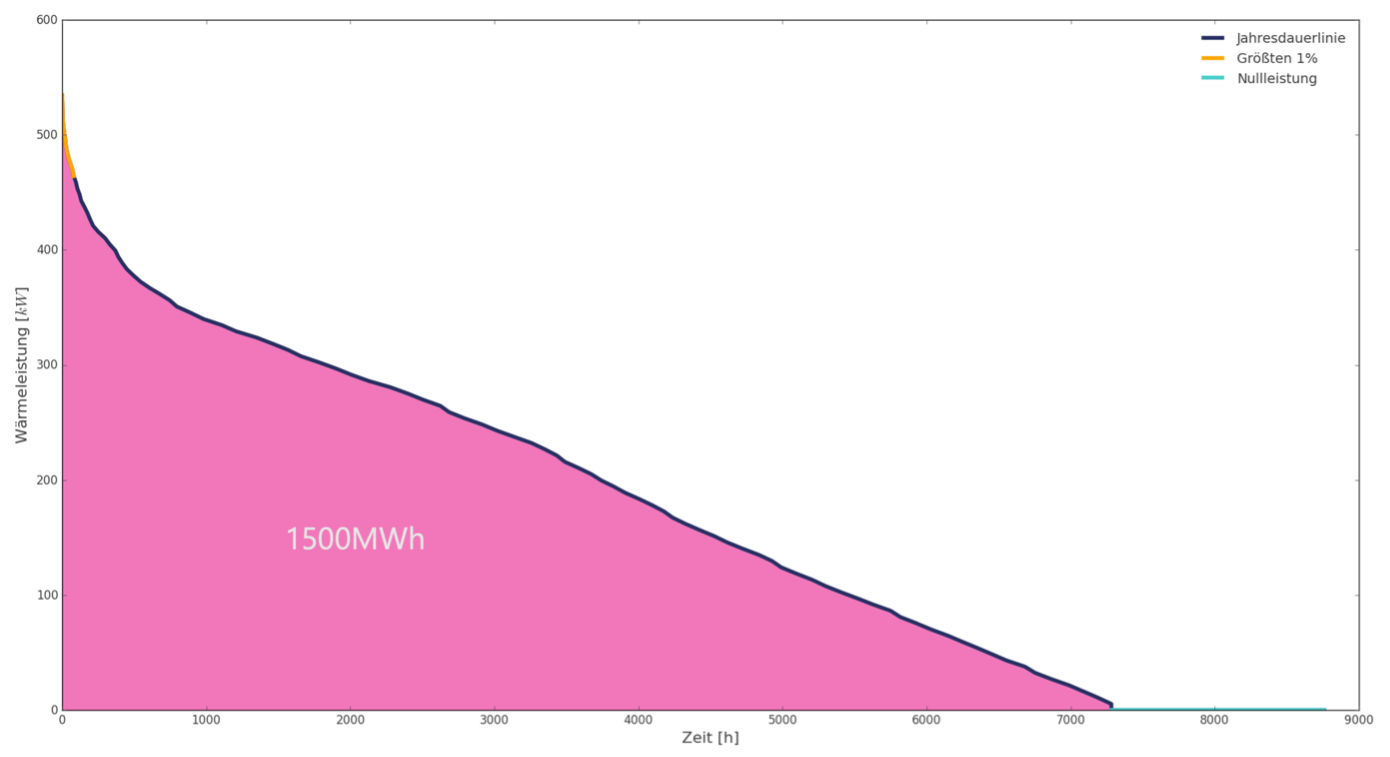

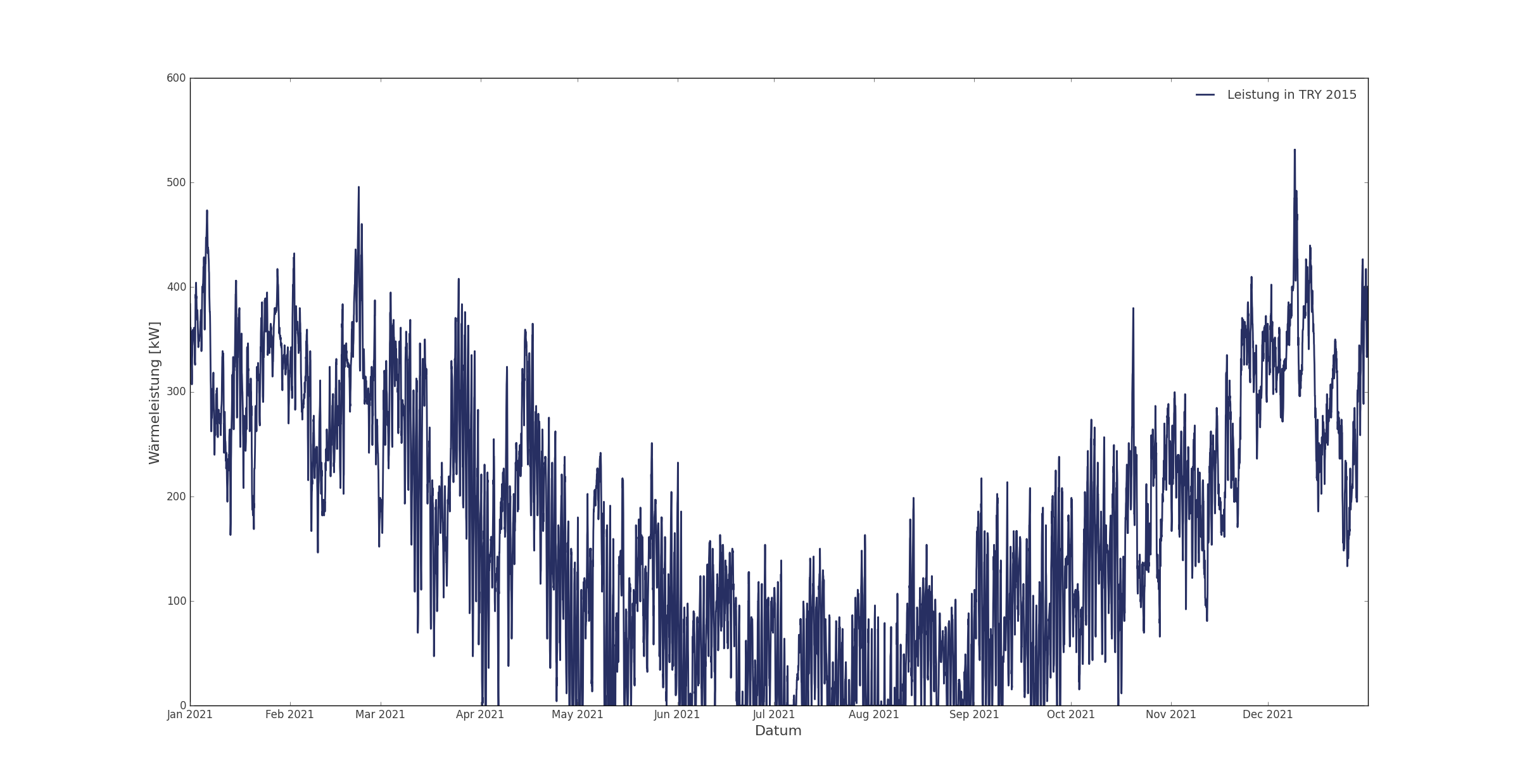

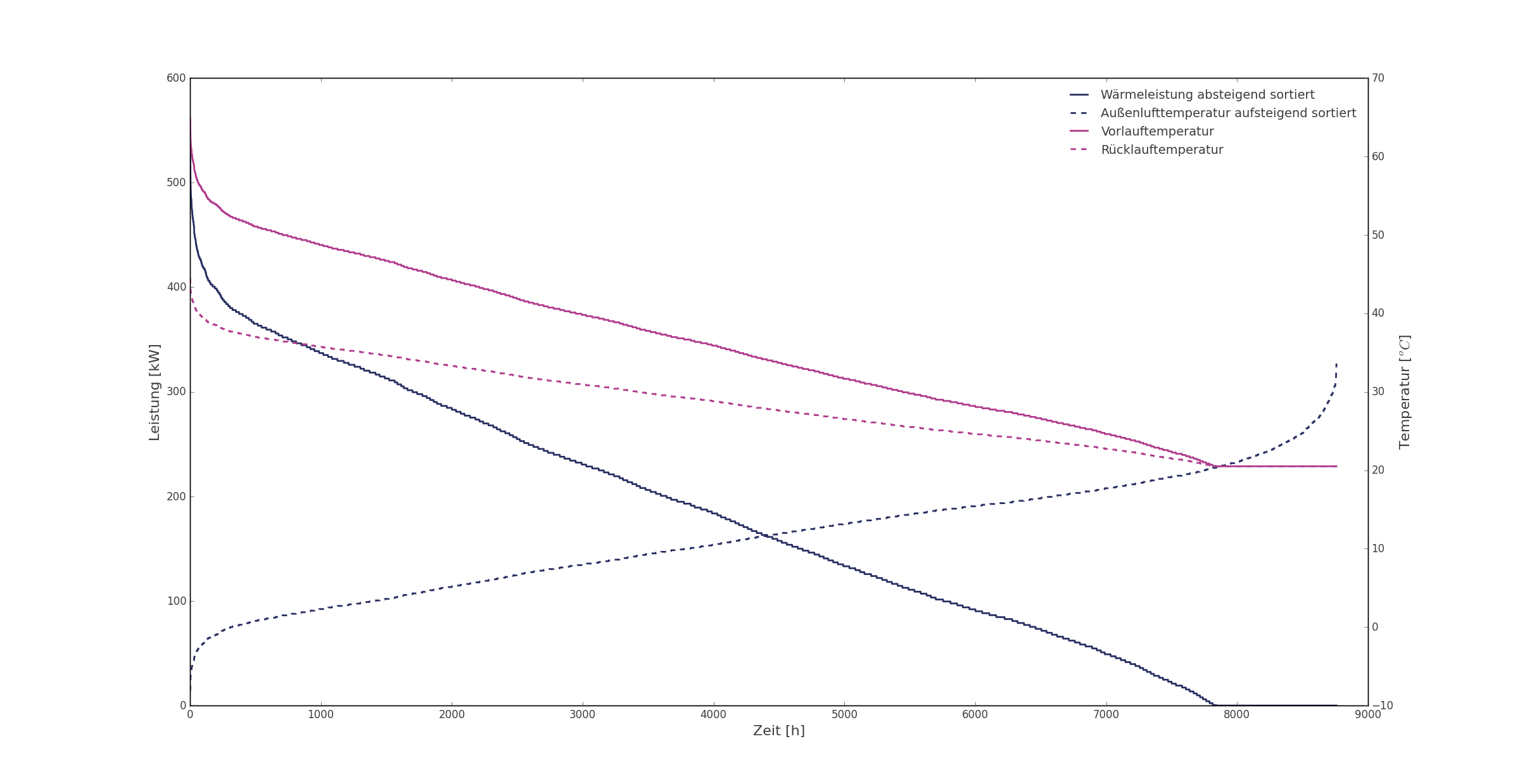

The heat power values are derived from the energy demand values and after sorting in descending order they form the annual duration curve shown in Figure 2. The annual duration curve contains a part with zero heat demand (green) and a part with the greatest heat power of 1% (orange). Both parts and not considered when the heat demand model for the building is calculated.

Figure 2: Annual duration curve of the heat power

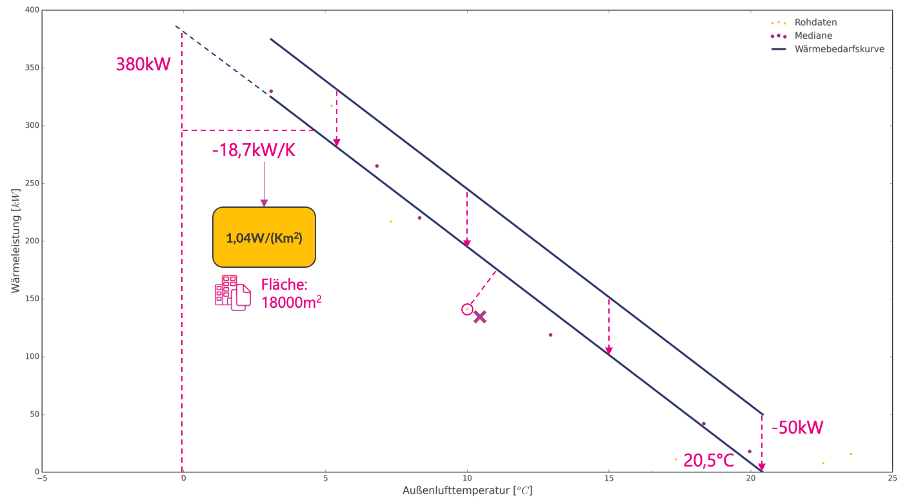

With the help of the remaining parts of the annual load duration curve the heat demand model is fitted. The fitted model can be seen in Figure 3. The model requires information about the outside air temperature at every heat power observation. The values for the outside air temperature are obtained from the weather station component. With the power values assigned to the corresponding outdoor air temperature, a regression can be calculated to determine the heat demand as a linear function over the outside air temperature. As shown in Figure 3, the function has a slope of 18.7 kW/K and a heating power of 380 kW at an outside air temperature of 0 °C.

[ ]

]

Figure 3: Heat demand curve with base load power

Assuming a heating limit temperature of 20.5 °C, the basic heat output power requirement is 50 kW for e.g. hot water.

By determining a model for the heating behavior of the building in a reference period, a comparability with an analysis period can be achieved. If the heat energy demand in the analysis period has decreased by more than 5%, compared to the reference period, an energy saving is recognized as shown in Figure 4

Signal colors

| Signal color | Energy deviation | Info |

|---|---|---|

| red | positive | Energy consumption deviation > 5 % |

| yellow | equal | Energy consumption nearly equal |

| green | negative | Energy consumption deviation < -5 % |

Interpretations

| Signal color | Info |

|---|---|

| red | Energy losses are too high |

| yellow | Neither savings nor losses detected |

| green | Energy savings detected |

Recommendations

| Signal color | Info |

|---|---|

| red | Check in detail why the heat consumption has increased |

| yellow | - |

| green | Heat consumption has decreased |

KPIs

Summary KPI

Note

try: test reference year

anls: analysis period

| KPI reference | Info | Value Range | Unit |

|---|---|---|---|

| heat demand curve.offset | heat demand power \(\dot{Q}(\vartheta = 0\) \(^oC)\) | > 0 | kW |

| heat demand curve.slope | heat demand power slope \(m = \frac{d\dot{Q}}{d\vartheta}\) | < 0 | kW/K |

| heat demand curve.slope.specific | heat demand power slope \(m_A = \lvert \frac{m}{A} \rvert\) | > 0 | kW/Km2 |

| heat demand curve.outside temperature heating limit | heating limit temperature \(\vartheta_{limit}\) | > 0 | °C |

| heat demand curve.base load power | heat base load power \(\dot{Q}_{water}(\vartheta >= \vartheta_{limit})\) | > 0 | kW |

| test reference year.hot water demand.model-based | hot water energy in test reference year \(Q_{water} = \int\dot{Q}_{water}\) \(dt\) for \(T = T_{try}\) | > 0 | MWh |

| test reference year.total heat demand.model-based | total energy in test reference year \(Q_{total} = \int\dot{Q}_{total}\) \(dt\) for \(T = T_{try}\) | > 0 | MWh |

| test reference year.heat demand.model-based | heat energy in test reference year \(Q_{heat} = Q_{total} - Q_{water}\) | > 0 | MWh |

| analysis period.total heat demand.model-based | total energy in analysis period calculated by model \(Q_{total}\) for \(T = T_{anls}\) | > 0 | MWh |

| analysis period.hot water demand.model-based | hot water energy in analysis period calculated by model \(Q_{water}\) for \(T = T_{anls}\) | > 0 | MWh |

| analysis period.heat demand.model-based | heat energy in analysis period calculated by model \(Q_{heat}\) for \(T = T_{anls}\) | > 0 | MWh |

| analysis period.total heat demand.measured | total energy in analysis period measured by meter \(Q_{meas}\) for \(T = T_{anls}\) | > 0 | MWh |

| total heat demand difference | difference between model based and measured total energy \(\Delta Q = Q_{model} - Q_{meas}\) | \(\mathbb{R}\) | MWh |

| total heat demand difference.relative | relative difference total energy \(q = \frac{\Delta Q}{Q_{model}}\) | \(\mathbb{R}\) | % |

| Pin | Required | Mapping info | Unit |

|---|---|---|---|

| - | - | - | - |

Choose Base load power or Heating limit temperature upper limit. Only one of both attributes is necessary. The other value will be calculated as KPI

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Heating limit temperature upper limit | Yes* | Temperature limit where the heating system is not active | °C |

| Net floor area | Yes | Used to calculate the per area KPI for current value | m2 |

| Reference period end | Yes | End of reference period to calculate model | YYYY-MM-DD |

| Reference period start | Yes | Start of reference period to calculate model | YYYY-MM-DD |

| Thermal base load | Yes* | Power consumption independent of heat demand | kW |

Sub-components

Adding the weather station is mandatory. The analysis uses the outside air temperature as one of two input values.

The larger the temperature interval, the more accurate the heat demand analysis. If there are several weather stations, the first one is selected in alphabetical order of the component in project name.

| Pin | Required | Mapping info |

|---|---|---|

| Temperature | Yes | Needed as one of the key input values |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| - | - | - | - |

At least only one meter component is needed to get a result for this analysis function.

| Pin | Required | Mapping info |

|---|---|---|

| Gas quantity | Yes | Cumulating timeseries in m3 |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Calorific value of natural gas | Yes | Change to calorific value of delivered natural gas. Default: 13 kWh/m3 | kWh/m3 |

| Pressure compensation factor of natural gas | Yes | Additional factor to compensate for elevation and line pressure at the termination point. Default: 1 | |

| Cost measurement device | Yes | Indicates whether it is a relevant meter | bool |

| Pin | Required | Mapping info |

|---|---|---|

| Heating energy | Yes | Cumulating timeseries in kWh |

| Attribute | Required | Mapping info | Unit |

|---|---|---|---|

| Cost measurement device | Yes | Indicates whether it is a relevant meter | bool |

Recommend Time Span

1 year, but at least one full heating period and one period without heating demand

Recommended Repetition

monthly

- Continuously monitor energy savings in comparison to the reference period

Heat Pump Investment¶

The Heat pump investment analysis is an extension of the heat demand analysis with a heat pump simulation and an economic efficiency calculation.

The user can vary the boundary conditions of the physical and monetary domain to check if a heat pump is economically feasible for the heating system.

An electric heating element is assumed as an additional part of the heating system. Its electrical energy consumption is taken into account in the calculation of the annual coefficient of performance. The electrical energy is assumed to be equal to the thermal energy.

Value

- Hourly operating point simulation depending on heat demand and environmental heat

- Choice of different heat pump models and technologies from several manufacturers

- Energy saving calculation and conversion in cost and CO2 emission savings potential

- Investment calculation depending on

- cost savings

- interest rate

- depreciation rate (optional)

Recommended for components

Building with gas heating or district heating

Checked conditions

- Heat energy consumption of the building

- Efficiency potential of heat pump usage

- Payback period for heat pump investment

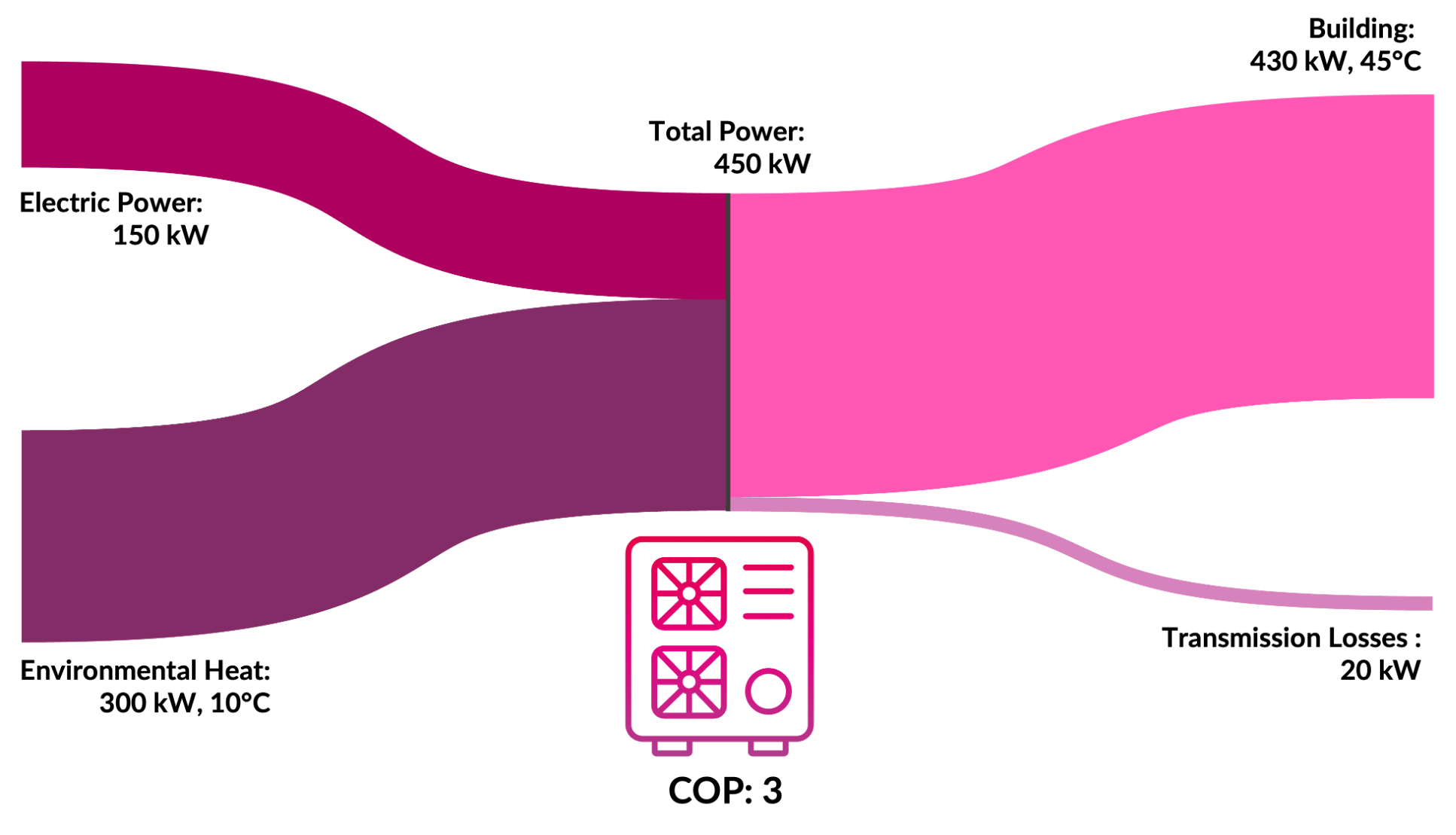

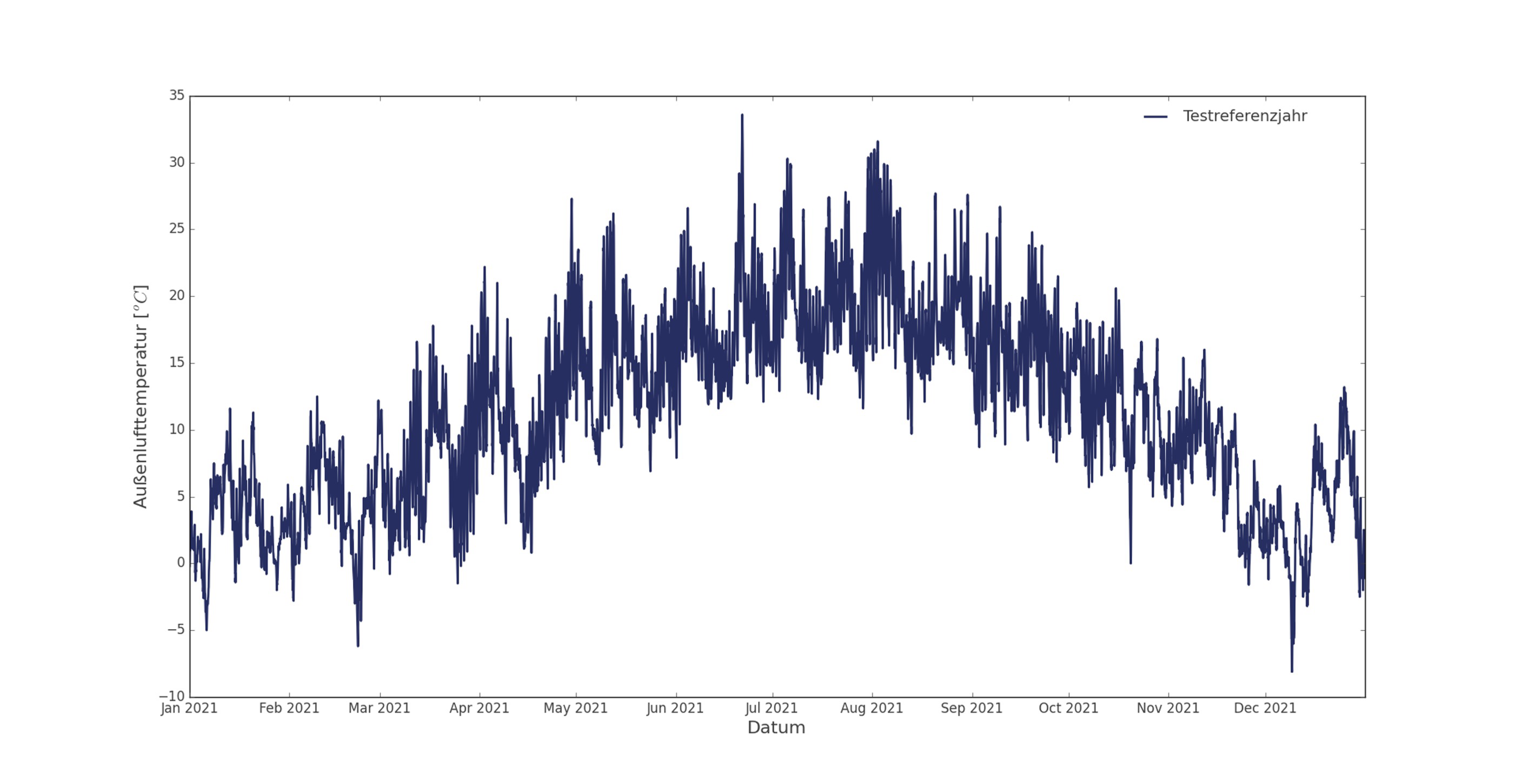

This example shows a simulation of an air/water heat pump. For a brief technical explanation, see Figure 1.

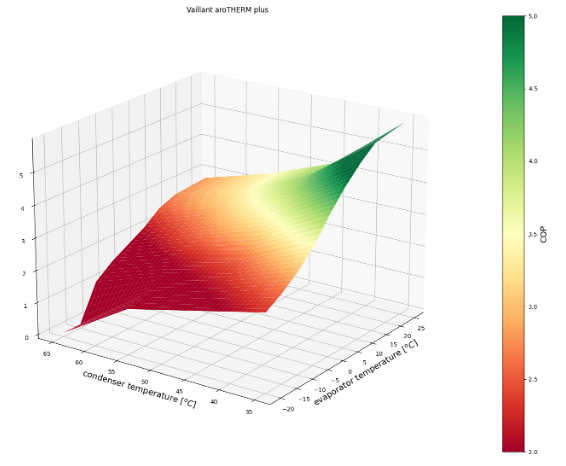

The schematic shows only one of several operating points with a coefficient of performance (COP) about 3. This means that with 150 kW of electric power, a heating power of 450 kW can be provided by taking 300 kW from the environment. In reality, small transmission losses occur, but they are neglected for this simulation.

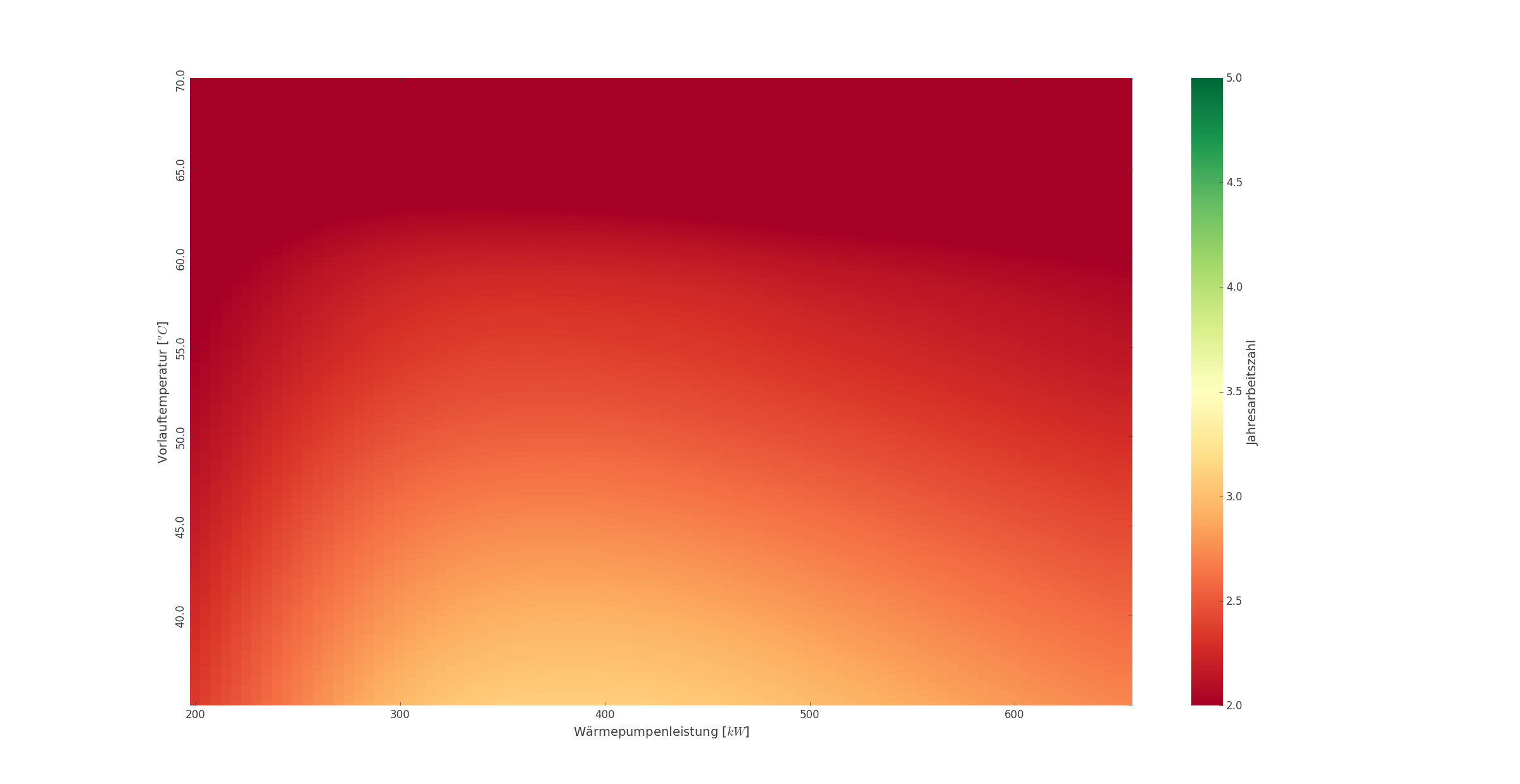

For a detailed simulation, all operating points must be taken into account. As shown in Figure 2, a coefficient of performance map is used to calculate several operating points, depending on the condenser and evaporator temperature. The evaporator temperature is nearly equal to the outside air temperature. Therefore, the outside air temperature acts as one of two input values. The condenser temperature is nearly equal to the supply temperature of the heating system. Therefore, the supply temperature acts as the second input value.

Figure 2: COP map air/water heat pump